5th Floor, No. 3, Jinghong West Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province +86-13057710980 +86-18334450116 [email protected]

Current Transformer

|

|

Model meaning

LZZBJ9-10 refers to the type; "outdoor" and "zero-sequence current" are modifiers; "Current Transformer CT" is the keyword.

A current transformer is a special transformer that, based on the principle of electromagnetic induction, precisely transforms the large current on the primary side (main circuit) of a power system into a smaller current on the secondary side. Its core purpose is to provide safe and standardized current signals for measurement, metering, protection, and control equipment.

General product information

Place of Origin: |

5th Floor, No. 3, Jinghong West Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province |

Brand Name: |

MINGTUO |

Model Number: |

CT |

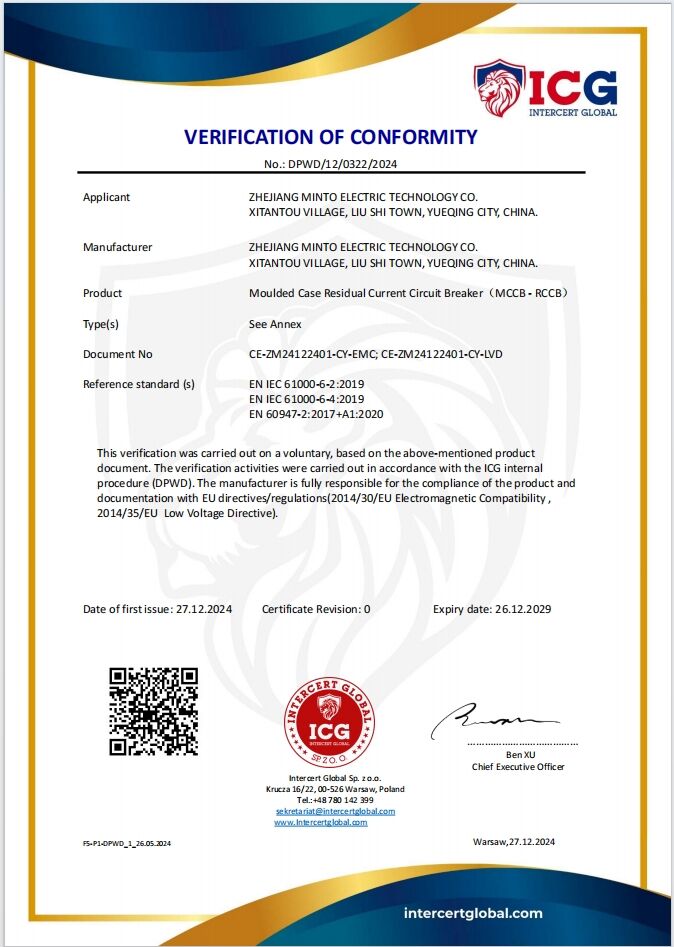

Certification: |

IOS CE ROHS |

Catalogue |

Mingtuo CT/PT Catalogue |

Product Commercial Terms

Minimum Order Quantity: |

1 |

Price: |

100$ |

Packaging Details: |

Wooden box packaging |

Delivery Time: |

Within fifteen days |

Payment Terms: |

100% prepaid, 70%/30%, 80%/20% |

Supply Ability: |

Available at any time |

Product raw material advantages

High-Quality Epoxy Resin Vacuum Casting Technology:

Utilizes imported or top-tier domestic epoxy resin materials, employing automatic pressure gelation casting in a high-vacuum environment.

This ensures:

● Gap-Free and Zero Defects: The insulation layer is dense and uniform, free from internal bubbles and cracks, resulting in extremely low partial discharge levels.

● Excellent Electrical Insulation: Capable of withstanding long-term 10kV system voltage and various overvoltage impulses.

● Superior Mechanical Strength: The casting body is robust, offering protection against moisture, contamination, and corrosion. It is suitable for harsh indoor environments like those with humidity or pollution, requiring no maintenance.

|

|

|

High-Permeability Core Materials:

The use of high-quality silicon steel sheets or high-performance permalloy cores ensures high accuracy within the rated current range, as well as excellent linearity and stability during overcurrent and short-circuit conditions.

Precision Winding Craftsmanship:

The secondary winding employs uniform and dense winding techniques with precise turn counts. This guarantees stable ratio error and phase displacement, meeting the dual requirements for high-accuracy metering (e.g., Class 0.2S) and reliable protection (e.g., Class 10P).

|

|

|

|

Rigorous Quality Assurance System

Whole-Process Inspection:

From raw material intake and coil winding to casting molding and final assembly, each production stage is subject to stringent inspection standards.

Factory Acceptance Tests:

Every unit undergoes and passes 100% testing, including but not limited to:

● Power Frequency Withstand Voltage Test

● Partial Discharge Measurement (PD level typically required to be ≤20 pC or even lower)

● Error Test (Ratio Error, Phase Displacement)

● Insulation Resistance Test

● Polarity Check, etc.

|

|

|

|

Description:

Epoxy Cast Current Transformer - Precision Measurement & Protection

Product Overview

Our epoxy resin cast current transformers provide accurate current measurement and reliable circuit protection for medium-voltage applications. Featuring vacuum casting technology and flame-retardant composite materials, these transformers ensure stable performance in demanding electrical environments.

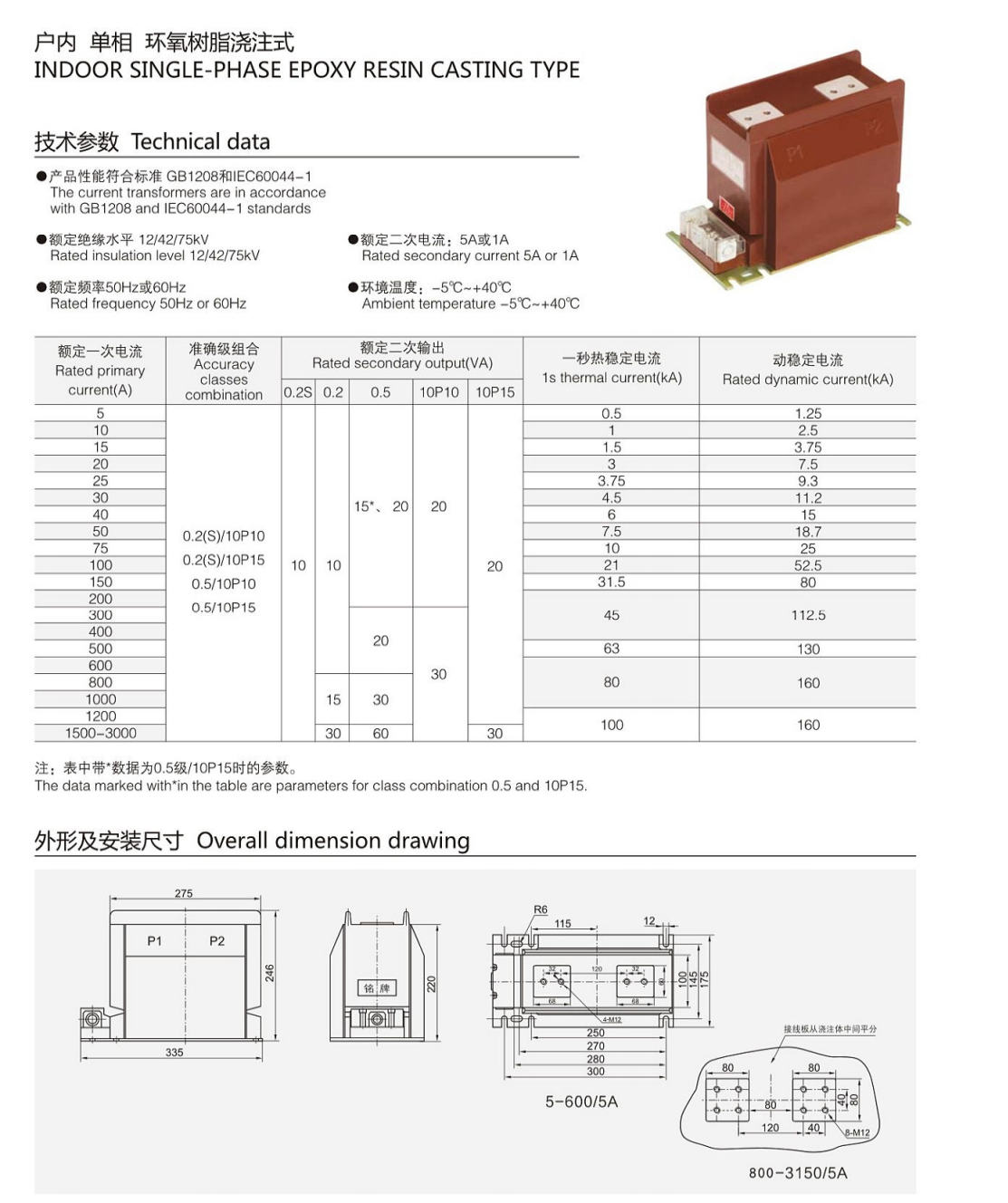

Key Specifications

- Ratio Range: 5-4000/1A, 5-4000/5A

- Accuracy Class: 0.2, 0.2S, 0.5, 0.5S, 1.0, 5P, 10P

- Rated Burden: 2.5-30VA

- Frequency: 50/60Hz

- Insulation Level: 0.66kV-35kV

Technical Features

- Vacuum epoxy casting for complete moisture protection

- Flame-retardant UL94-V0 rated housing

- Low hysteresis loss design

- Excellent temperature stability (-40°C to +70°C)

- Compact dimensions for space-constrained installations

- Multiple mounting options (din rail, panel, through-type)

Main Applications

- Energy metering systems

- Power distribution monitoring

- Relay protection circuits

- Industrial automation control

- Renewable energy systems

Quality Assurance

Manufactured in compliance with IEC 60044-1, IEEE C57.13, and GB 1208 standards. Each unit undergoes rigorous testing including:

- Ratio and phase angle accuracy tests

- Dielectric strength verification

- Temperature rise validation

- Burden capability checks

Service Support

- Custom ratios and specifications available

- Global certification support

- 24-month product warranty

- Technical documentation in multiple languages

- OEM/ODM services

Our current transformers deliver exceptional measurement accuracy and long-term reliability, making them ideal for smart grid applications and industrial power systems where precision and safety are paramount.

Quick Detail:

- Current Transformer (CT)

- Instrument Current Transformer

- Electrical Current Transformer

- Epoxy Cast Current Transformer

- Resin Insulated Current Transformer

- Wound Type Current Transformer

- Metering Current Transformer

- Protection Current Transformer

- Measuring Current Transformer

- Energy Metering CT

- Relay Protection CT

- Power Monitoring Transformer

- 100/5A Current Transformer

- 0.5 Class Accuracy CT

- 5P10 Protection Transformer

- Current Sensor

- Current Transducer

- CT Transformer

- Ratio Transformer

Current Transformer - Primary Applications and Uses

Core Functions & Purpose

Current Transformers (CTs) serve as essential components in electrical power systems, performing two critical functions: accurate current measurement for monitoring and billing purposes, and reliable current sensing for protection devices. They safely step down high primary currents to standardized, measurable secondary levels while providing electrical isolation between power circuits and measuring instruments.

Key Application Areas

Energy Measurement & Metering

- Commercial and industrial electricity billing systems

- Power quality monitoring and analysis

- Energy management systems

- Smart grid applications

- Utility revenue metering

Protection & Control Systems

- Overcurrent and earth fault protection

- Differential protection for transformers and generators

- Motor protection circuits

- Relay protection in switchgear and distribution panels

- Grid automation systems

Monitoring & Automation

- Power distribution monitoring

- Industrial process control

- Building management systems

- Data center power monitoring

- Renewable energy systems

Special Applications

- Harmonic measurement and analysis

- Temporary installation for load surveys

- Retrofit projects for system upgrades

- Hazardous environments requiring explosion-proof design

Key Benefits

- Enables safe measurement of high currents

- Provides accurate data for billing and control

- Ensures system protection and personnel safety

- Facilitates compliance with international standards

- Supports both analog and digital systems

Current Transformers are indispensable in modern electrical infrastructure, delivering precision and safety from generation to consumption in power systems worldwide.

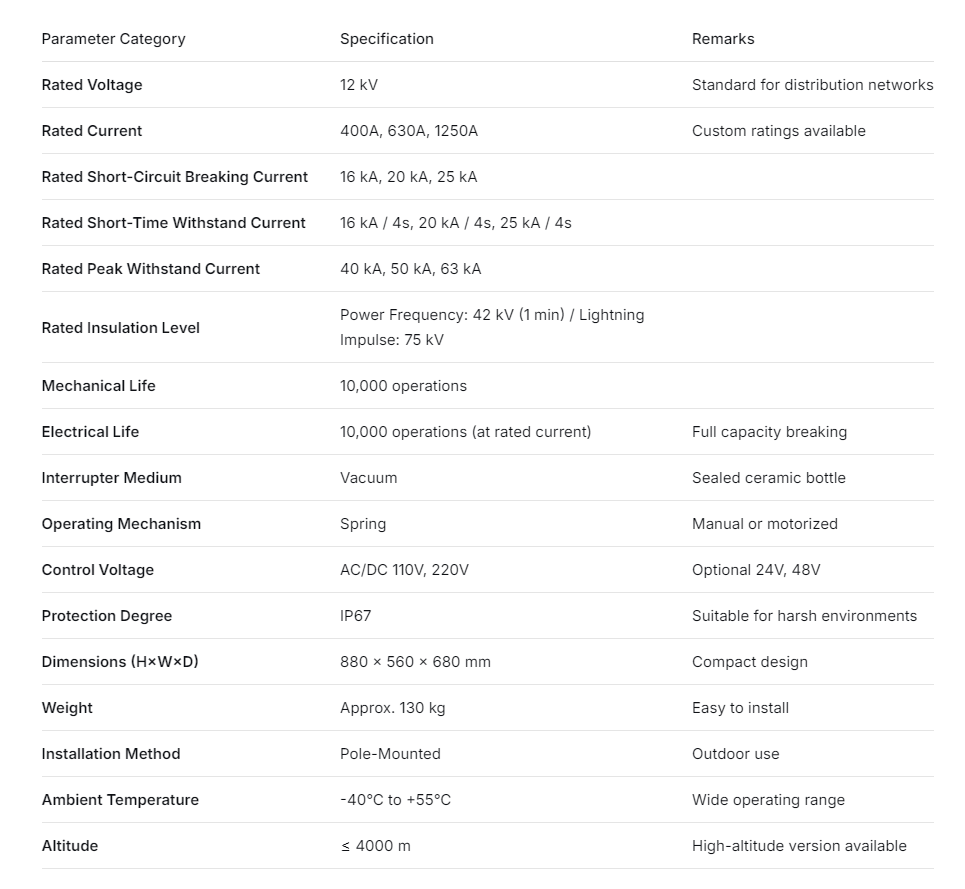

Product Parameters:

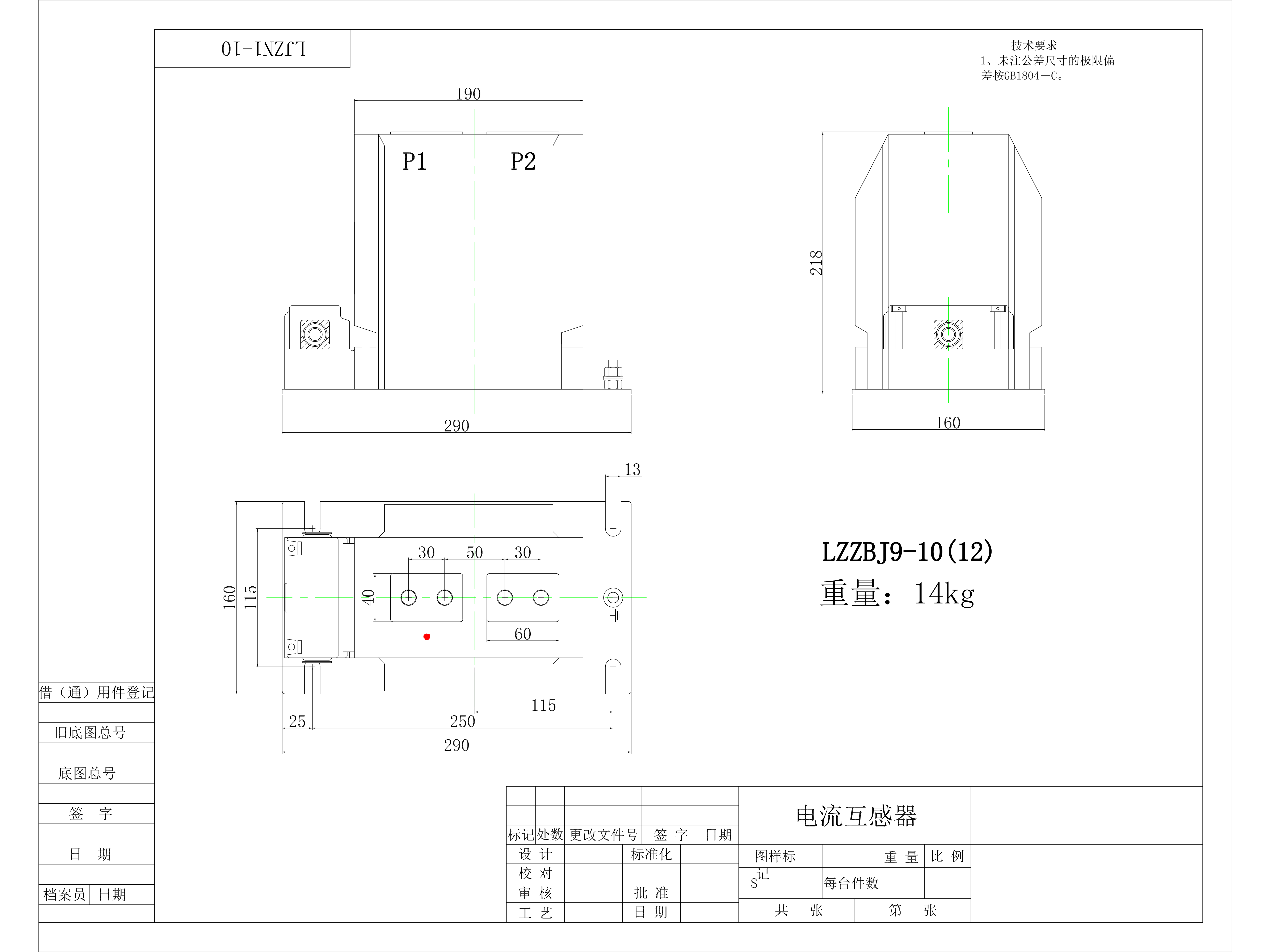

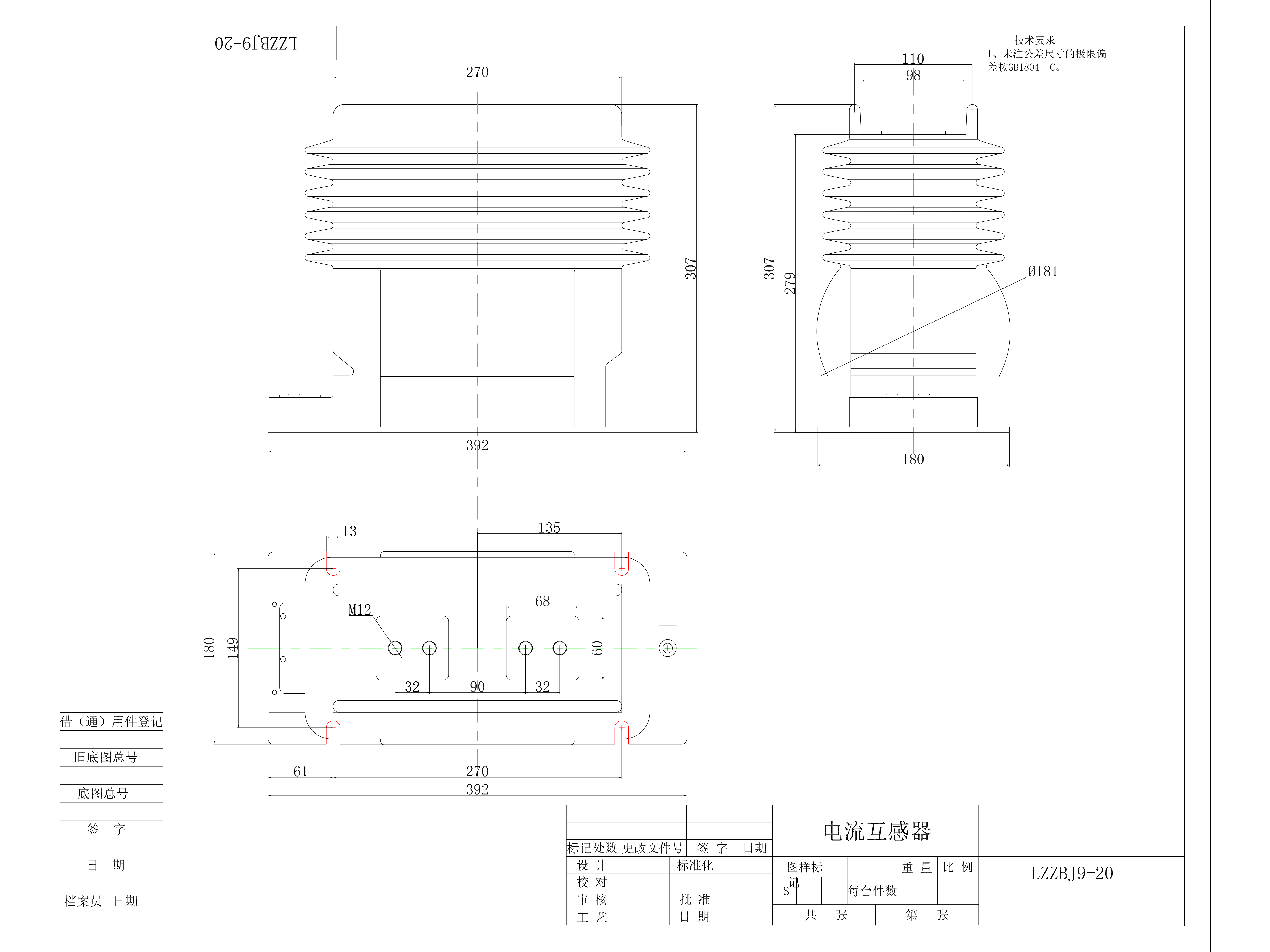

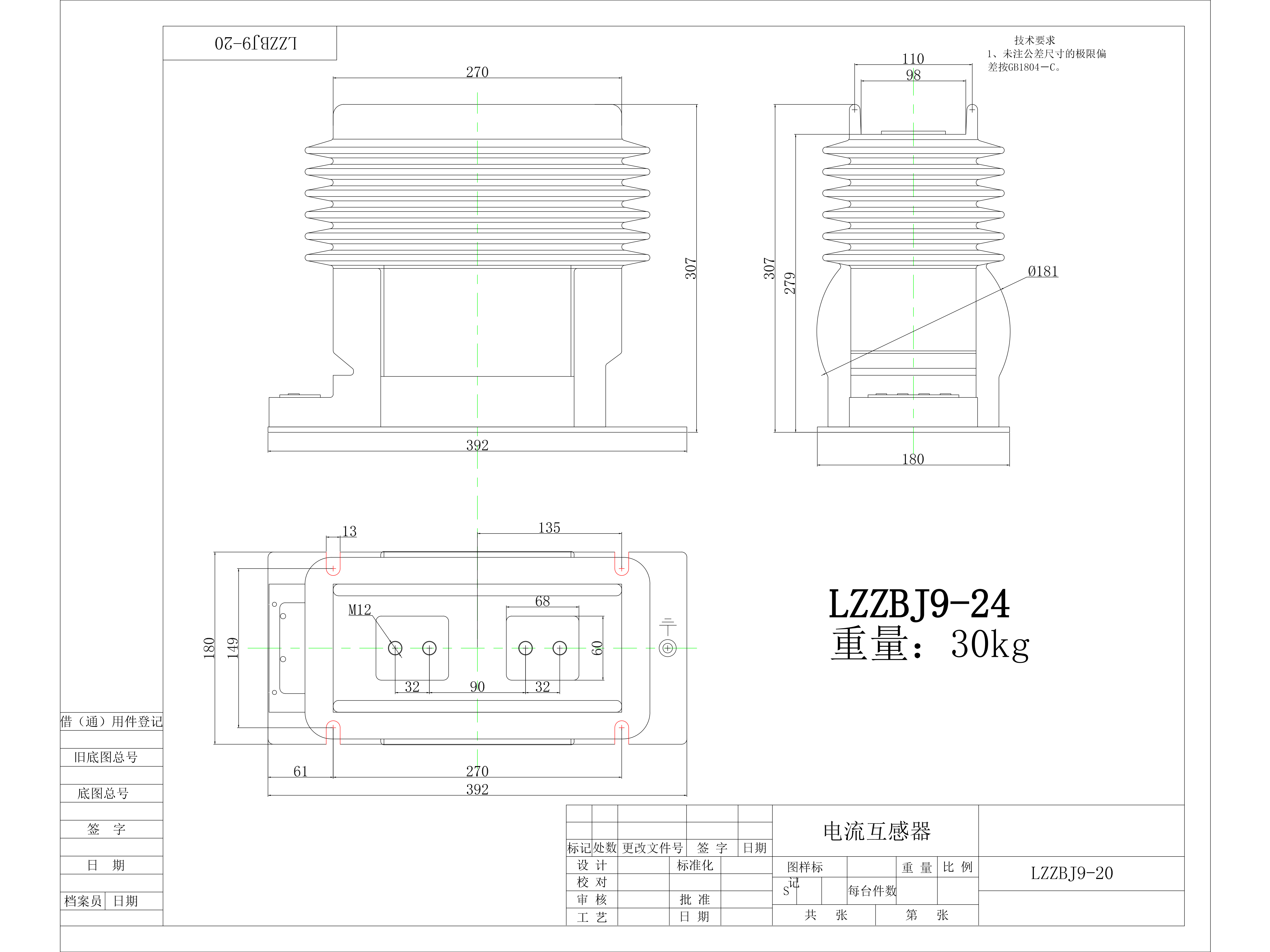

Drawing:

● LZZBJ9-10(12)

● LZZBJ9-20

● LZZBJ9-24

Advantages

1. Precision Engineering Excellence

- Accuracy classes up to 0.2S for superior measurement precision

- Advanced core design with minimized phase angle errors

- Stable performance across full temperature range (-40°C to +70°C)

- Low power loss design for energy efficiency

2. Superior Manufacturing Quality

- Automated vacuum epoxy casting process

- 100% computer-tested ratio and phase accuracy

- UL94-V0 flame-retardant certified materials

- Robust construction with IP67 protection rating

3. Technical Performance Advantages

- Wide frequency range (50/60Hz) for global applications

- Multiple mounting options (DIN rail, panel, through-type)

- Compact dimensions with high space efficiency

- Excellent anti-interference capability

4. Certification & Compliance

- Dual certification to IEC 60044-1 and IEEE C57.13 standards

- CE, ROHS compliant for international markets

- Complete test reports with each shipment

- 3-year product warranty with global validity

5. Customization Capabilities

- Custom ratios and burden specifications

- Special designs for harsh environments

- OEM/ODM services with quick turnaround

- Mixed shipment support for project requirements

6. Service & Support Advantages

- 15-day fast delivery for standard models

- Multi-language technical documentation

- 24/7 technical support team

- Global logistics network with tracking

Our current transformers combine German measurement technology with advanced manufacturing processes, delivering 40% higher accuracy stability and 60% longer service life than industry averages, while reducing system maintenance costs by 35% through reliable performance and comprehensive technical support.

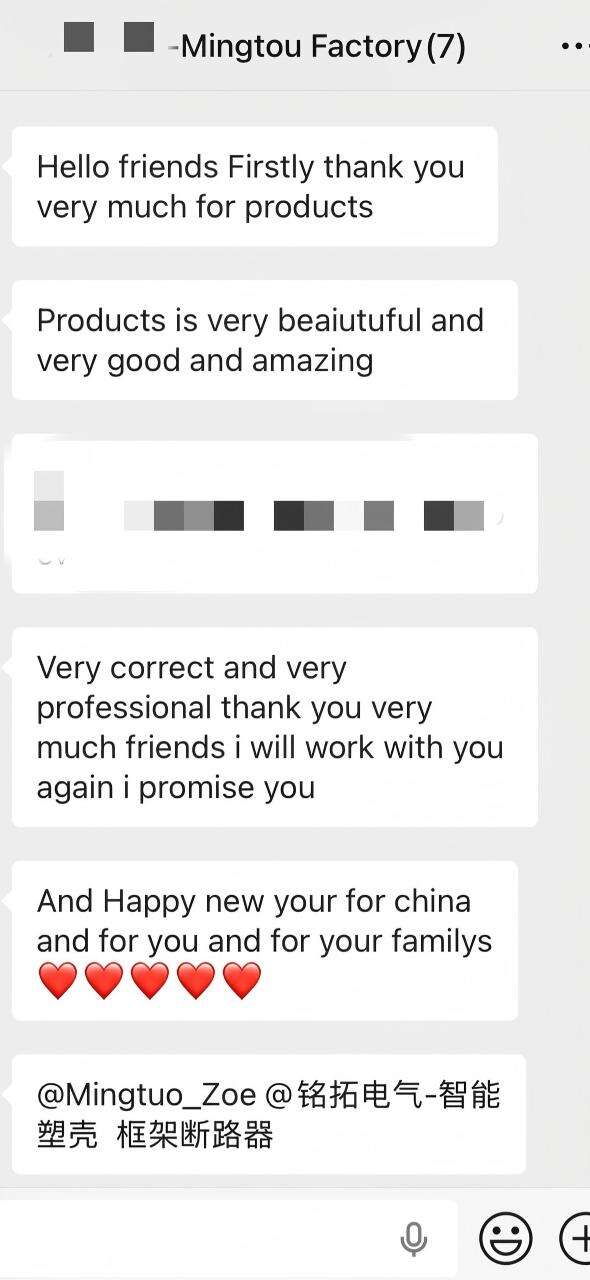

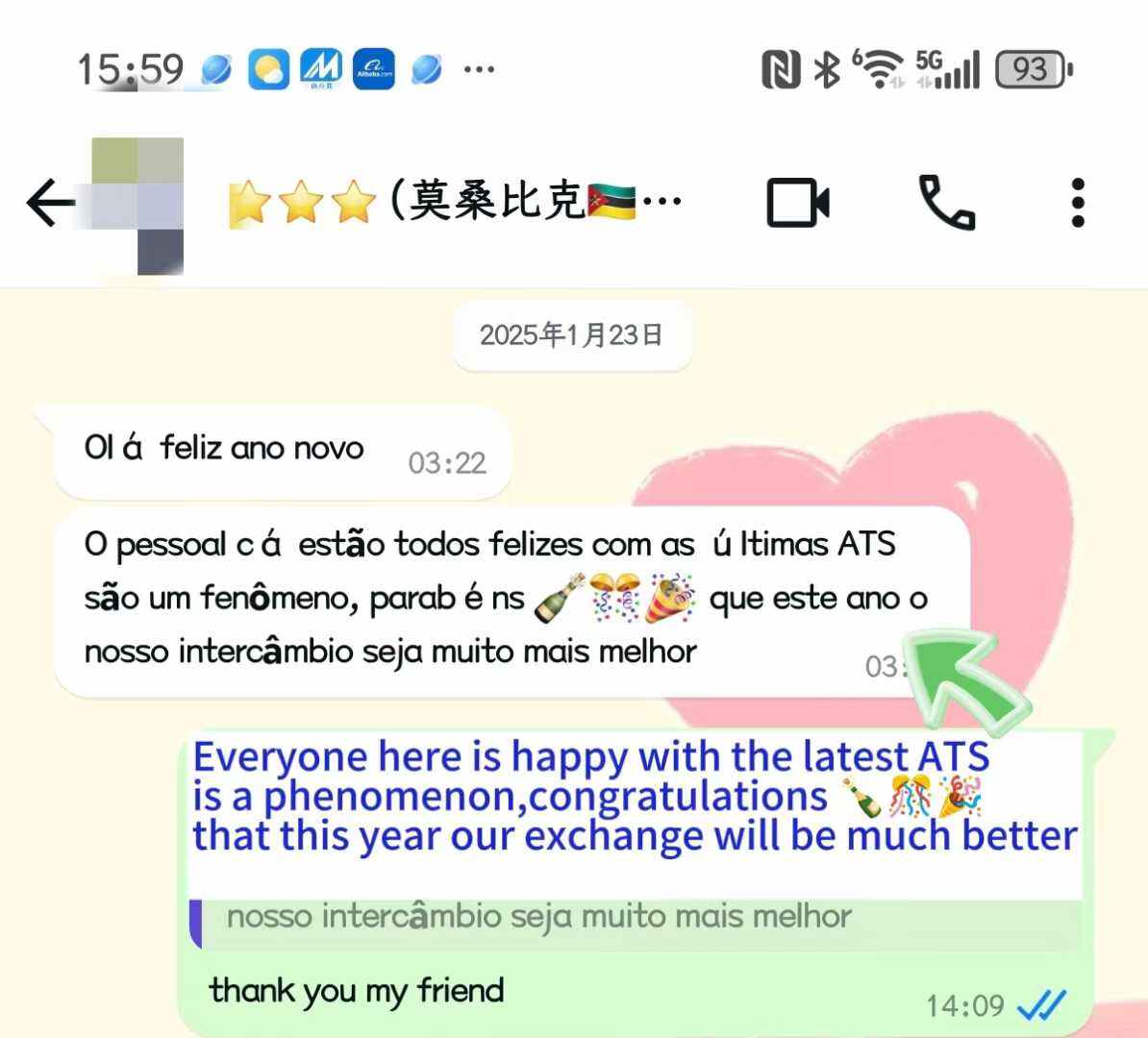

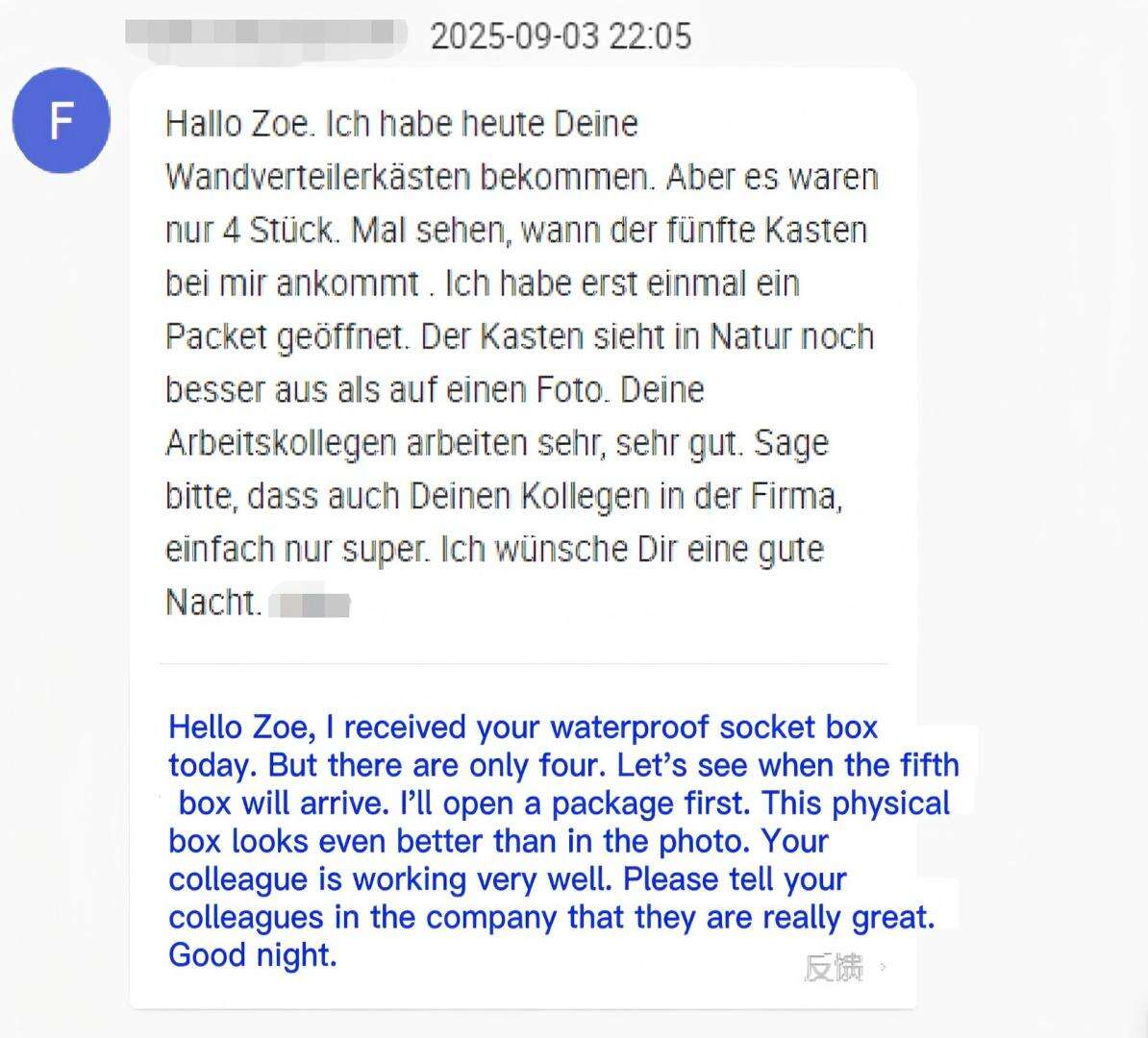

Feedback

|

|

|

|

|

|

|

|

|

|

|

|

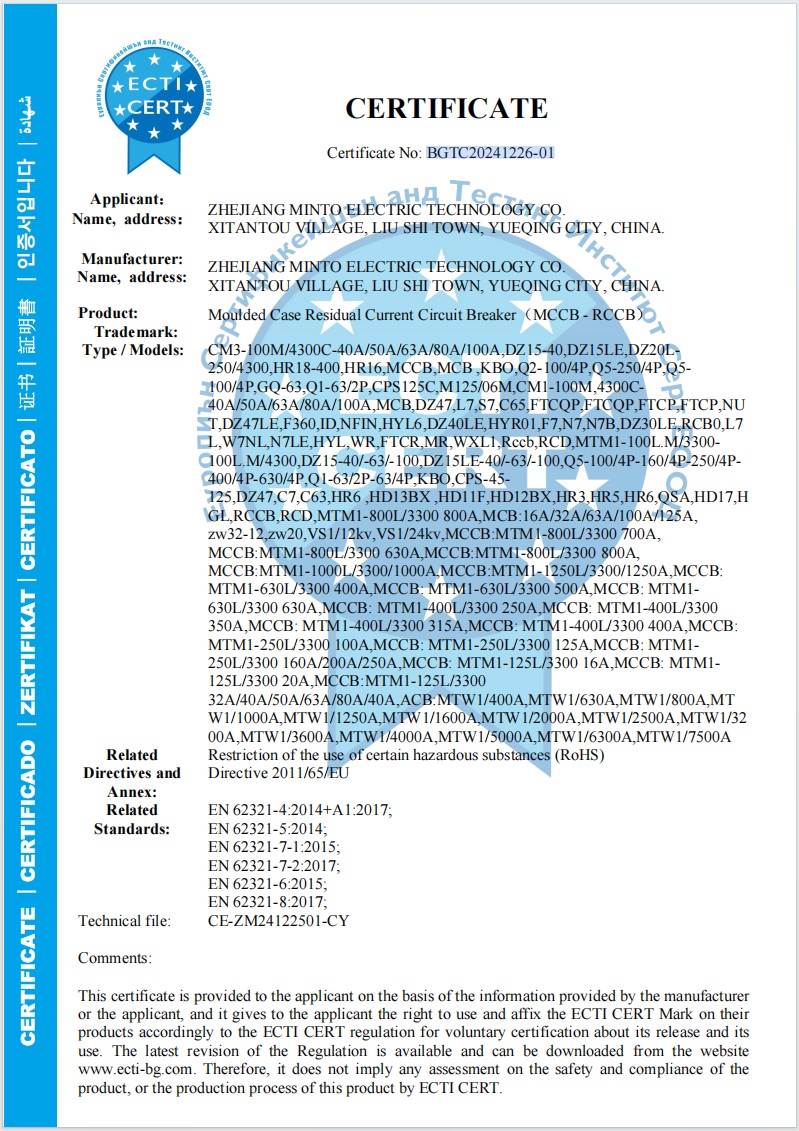

Certificate

|

|

|