5th Floor, No. 3, Jinghong West Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province +86-13057710980 +86-18334450116 [email protected]

VACUUM CIRCUIT BREAKER

630A/1250A/1600A/2000A/2500A/3150A/4000A

12kV/24kV/35kV

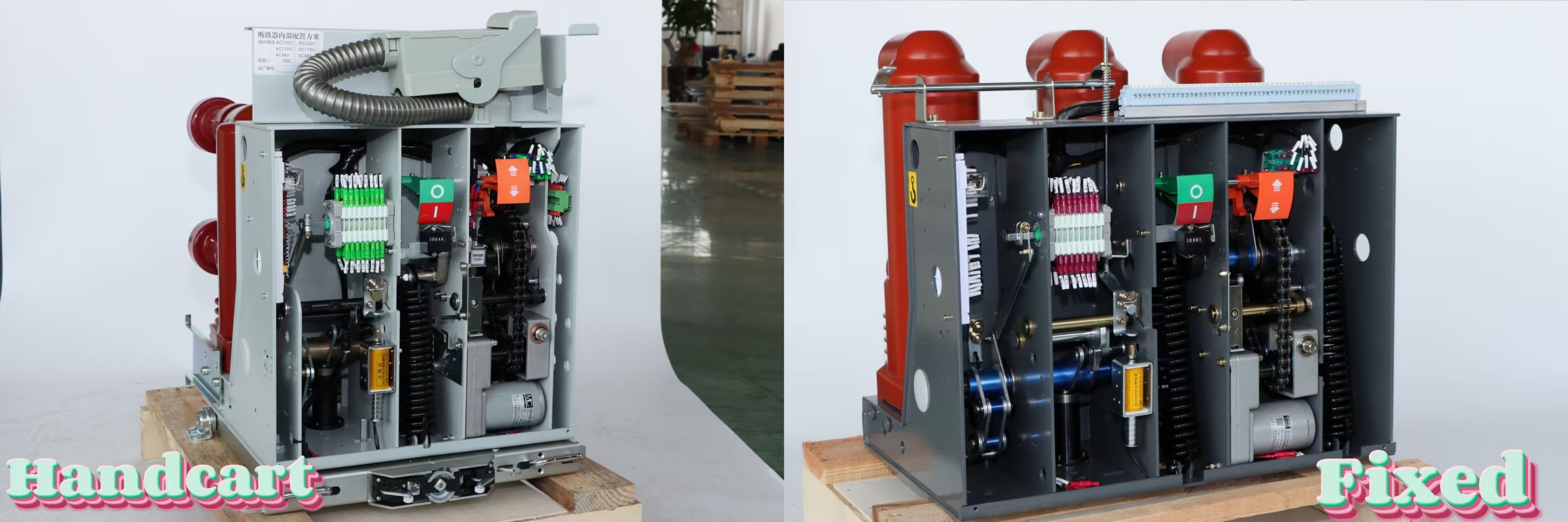

FIXED TYPE

|

|

|

HANDCART TYPE

|

|

|

ZN63(VS1) series vacuum circuit breaker is used for rated voltage isolator 12kV-35kV, 3-phase switch device, the indoor as grid equipment, industrial and miningenterprises, power equipment control and protection unit. Due to the specialadvantage, vacuum circuit breaker products suitable for the current requirementsrated frequent operation, or multiple open short-circuit current.By the integral layout structure, breakers used spring operation mechanism ismature, simple structure and reliable performance. The reasonable construction,make each points clear, functional units to decorate maintenance.

ZN63(VS1) vacuum circuit breaker in the form of installed within theswitch can be fixed, also can be drawn. From 630A - 4000A rated current ratingfrom 20KA-31.5KA short-circuit current, real serialized form.

Model meaning

The ZN63 high-voltage circuit breaker (often also known as the VS1 circuit breaker, VS1 being its most common model designation) is an indoor-installed medium-voltage circuit breaker employing vacuum arc-extinguishing technology. It is widely used in three-phase AC 50Hz power systems with rated voltages from 3.6kV to 12kV, serving as a protective and control device for power equipment, and is one of the core switching devices in modern substations and industrial and mining enterprise power distribution systems.

|

Core Features

Adopting high-performance vacuum arc extinguishing chamber, strong breaking ability, no explosion risk, environmentally friendly and pollution-free. Modular design The spring energy storage operating mechanism has a fast opening and closing speed and a mechanical lifespan of 10000 to 30000 times. Safety protection Fully enclosed insulation structure, protection level IP3X, dustproof and moisture-proof. Standards Compliant with international/domestic standards such as GB/T 1984 and IEC 62271-100. |

|

General product information

Place of Origin: |

5th Floor, No. 3, Jinghong West Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province |

Brand Name: |

MINGTUO |

Model Number: |

VCB(ZN63)MTV1 |

Certification: |

IOS CE ROHS |

Product Commercial Terms

Minimum Order Quantity: |

1 |

Price: |

500$ |

Packaging Details: |

Wooden box packaging |

Delivery Time: |

Within fifteen days |

Payment Terms: |

100% prepaid, 70%/30%, 80%/20% |

Supply Ability: |

Available at any time |

Product Parameters

| Model NO. | MTV1-12/630-25kA | Speed | High-Speed Circuit Breaker |

| Arc-extinguishing Medium | Vacuum | Installation | Fixed |

| Structure | Vcb | Poles Number | 3 |

| Type | Circuit Breaker | Function |

Conventional Circuit Breaker, Circuit-Breaker Failure Protection, Overcurrent Protection, OVP(Overvoltage Protection),RCCB |

| Certification | ISO9001-2000,CE,CCC,RoHS | ICU | 20ka-31.5ka |

| Voltage | 12kv/24kv/35kv | Current | 630A-4000A |

| Usage Environment | Indoor | Rated Frequency | 50Hz/60Hz |

| Control Voltage | AC110/220 DC110/220 | Transport Package | Wooden Crate |

| Specification | 69*51*74 | Trademak | Mingtuo |

| Origin | Zhejiang,China | HS Code | 8535210000 |

Main specifications and technical parameter

| No | Item | Units | Count value | No | Item | Units | Count value | ||

| 1 | The rated voltage | kV | 12 | 14 | Break-brake time (rated voltage) | ms | ≤50 | ||

| 15 | Feeder time (rated voltage) | ≤100 | |||||||

| 2 |

The rated voltage(short-term frequency tolerance 1min) |

42 | 16 | Mechanical life | Secondary | 20000 | |||

| 17 | Rated current open circuit times (life) | 20000 | |||||||

| 3 |

The rated voltage tolerance lightning shocks peak) |

75 | |||||||

| 18 | Rated short-circuit curent open circuit | 50(40kA≤30) | |||||||

| 4 | Rated frequency | Hz | 50 | 19 | Dynamic and static contactor allow wear thickness | mm | 3 | ||

| 20 | The rated operating voltage feeder | V | AC110/220 DC110/220 | ||||||

| 5 | Rated current | A |

630 1250 |

630 1250 1600 2000 2500 3150 |

1250 1600 2000 2500 3150 4000* |

||||

| 21 | The rated voltage break-brake operations | ||||||||

| 22 | Storage motor rated voltage | ||||||||

| 23 | Storage motor power rating | w | 70 | ||||||

| 6 | Rated short open circuit current | kA | 20/25 | 31.5 | 40 | ||||

| 24 | Storage time | s | ≤10 | ||||||

| 7 | The rated voltage short tolerance | 20/25 | 31.5 | 40 | 25 | Contact opening distance | mm | 11±1 | |

| 26 | Super-trip | 3.5±0.5 | |||||||

| 8 | Rated short duration | S | 4 | ||||||

| 27 | Closing contact bounce time | ms | ≤2(40kA≤3) | ||||||

| 28 | Three-phase points,closing at diferent stages of sexual | ≤2 | |||||||

| 9 | Rated current peak tolerance | kA | 50/63 | 80 | 100 | ||||

| 29 | Average gate speed(contact separation-6mm) | m/s | 0.9-1.2 | ||||||

| 50/63 | 80 | 100 | |||||||

| 10 | Rated short-circuit current close | 30 | Average closing speed(6mm-contact closure) | 0.5-0.8 | |||||

| 31 | Leading electric circuit resistance | μΩ |

≤50(630a) ≤45(1250A) ≤35(1600-2000A) ≤(2500A above) |

||||||

| 11 | The secondary circuit frequency voltage tolerance 1min) | V | 2000 | ||||||

| 12 | Rated single/back capacitor set open circuit current | A | 630/400(40kA 800/400) | 32 | Contactor feeder contact pressure | N |

2000±200(20kA) 2400±2000(25kA) 3100±200(31.5kA) 4250±250(40kA) |

||

| 13 | Rated capacitor set close currents | kA | 12.5 (frequency no greaterthan 1000Hz) | ||||||

Technical Data for opening and closing Coils

| / | Closing Coil | Opening Coil | Remarks |

| Rated Operating Voltage(V) |

DC220,DC110 AC220,AC110 |

DC220,DC110 AC220,AC110 |

Opening coil current must not be less than 30%of the rated operating voltage. |

| Coil Power(W) | 245 | 320 | |

| Normal Operating Voltage Range | 85%-110% of Rated Voltage | 85%-120% of Rated Voltage |

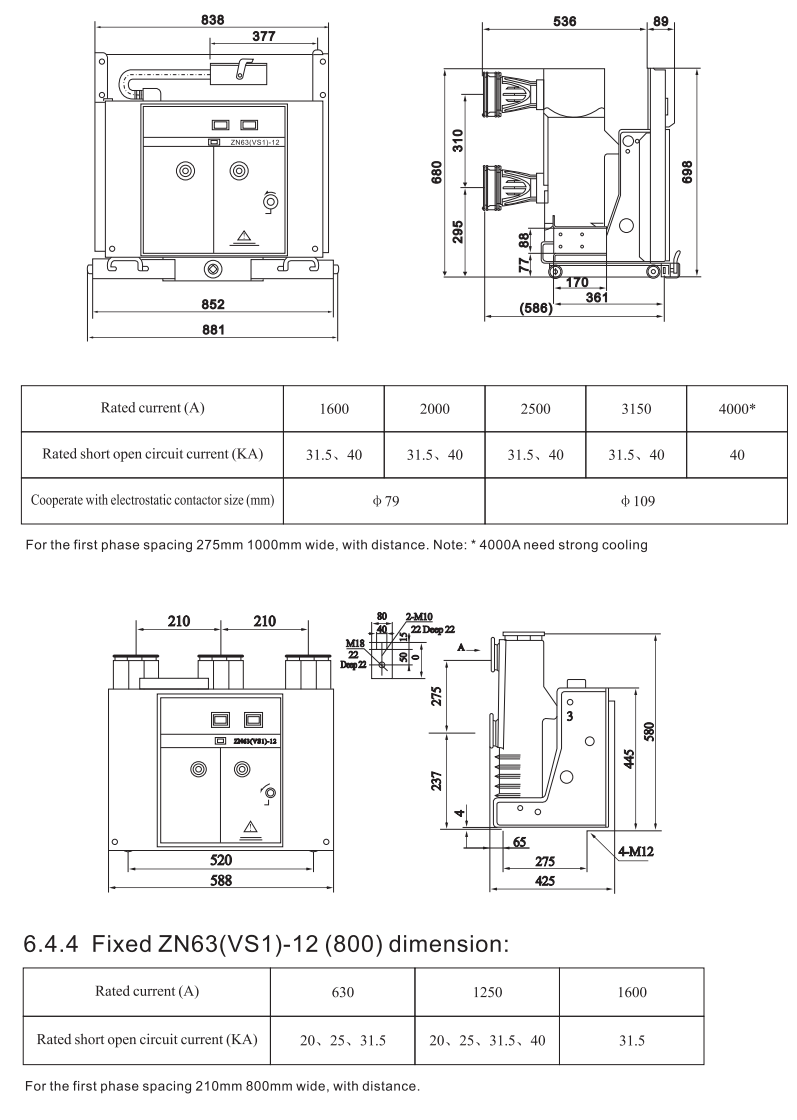

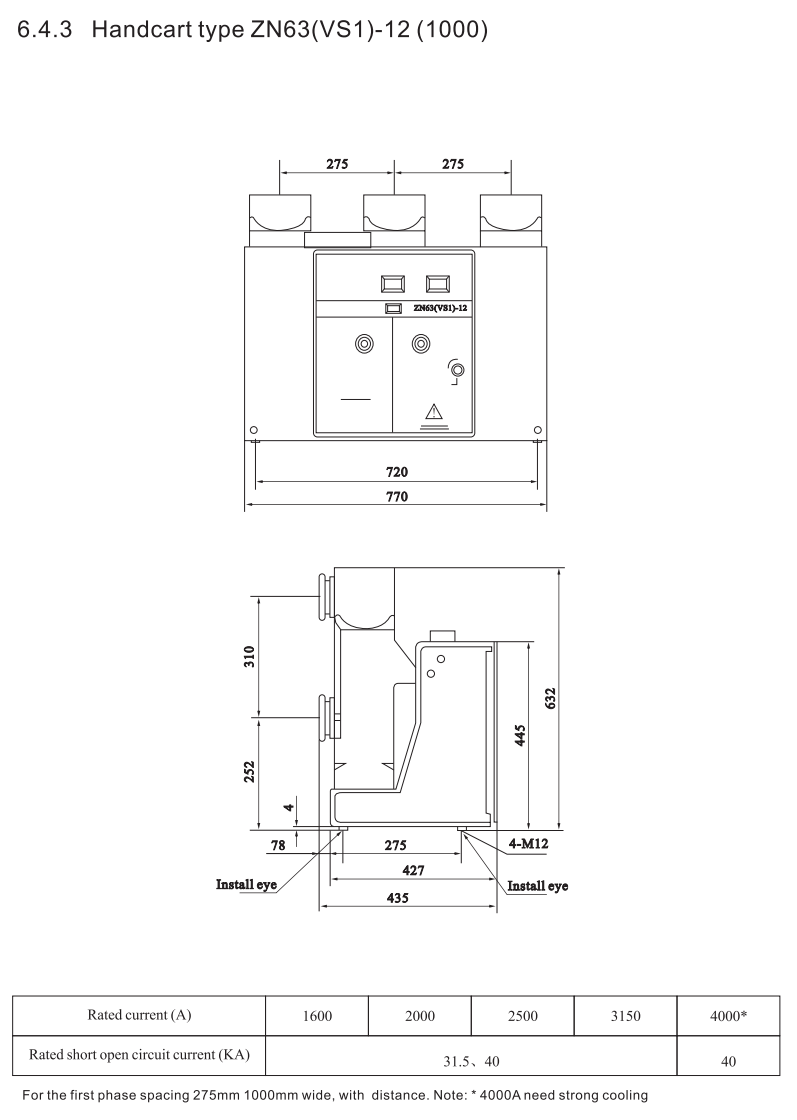

Product dimensions

|

|

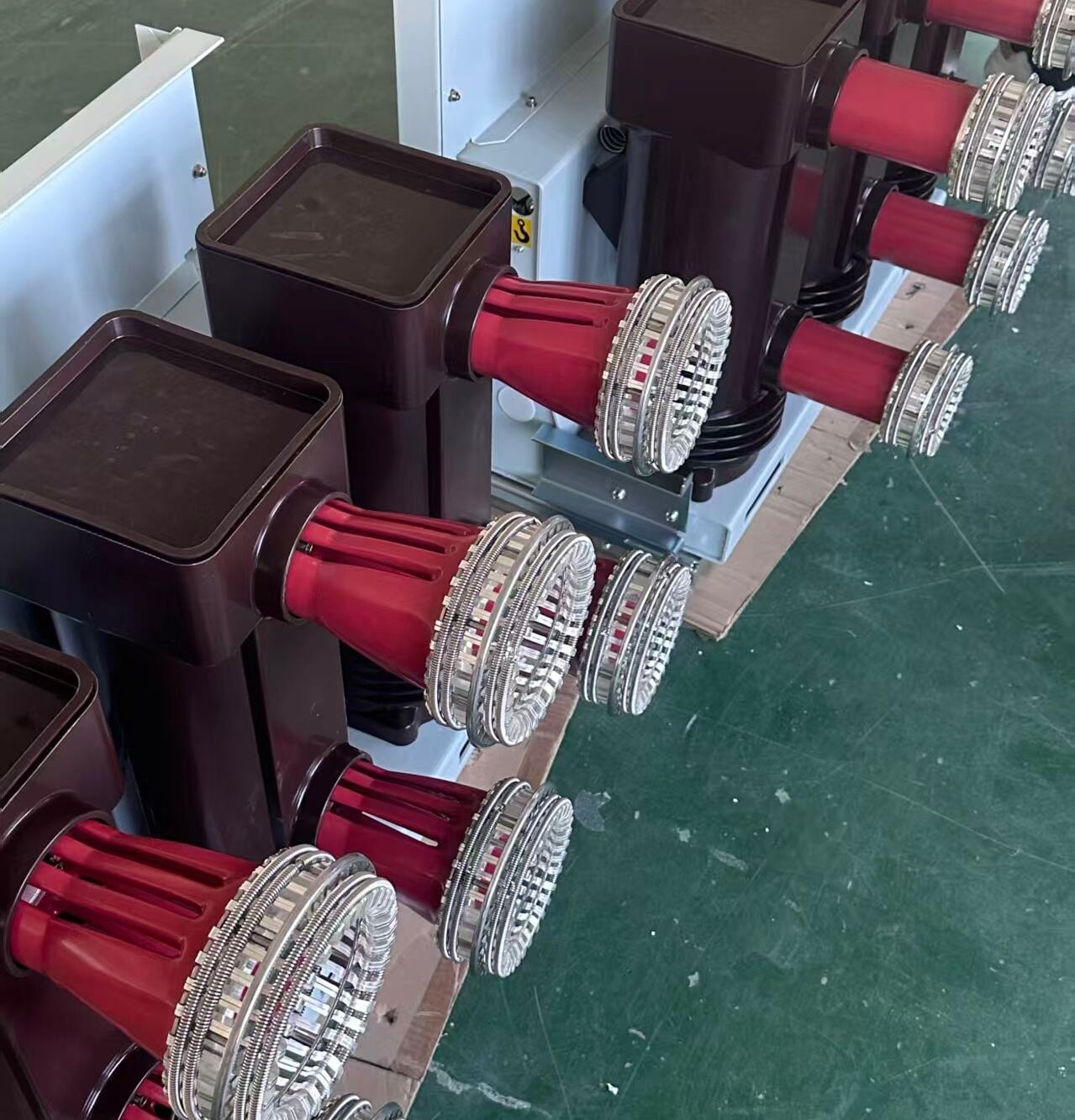

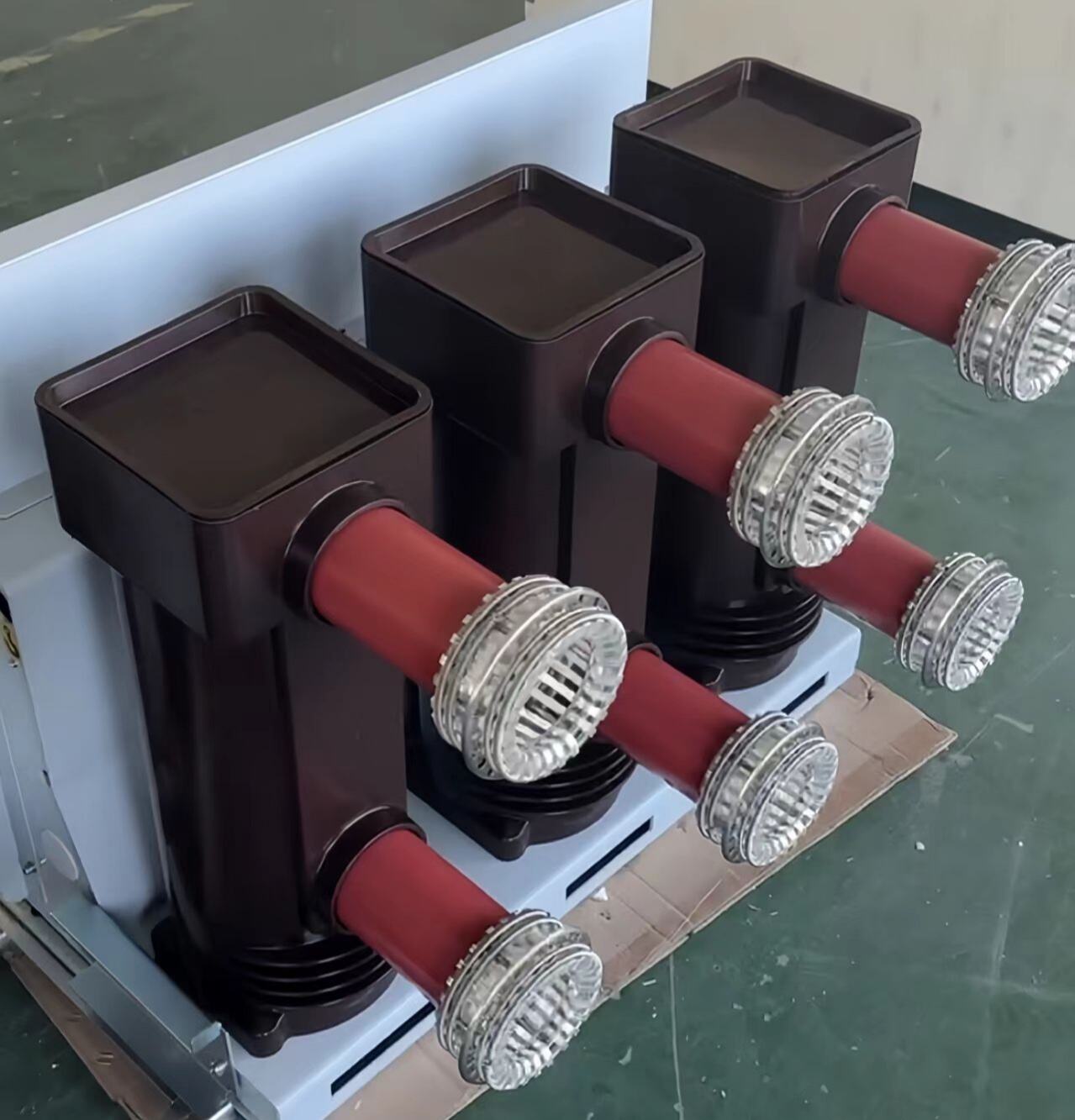

High current products

|

|

|

Environmental conditions for use

Normal Operating and Installation Conditions

Ambient Air Temperature

Atmospheric Conditions

The relative humidity must not exceed 50% at an ambient air temperature of +40°C. Higher relative humidity is permitted at lower temperatures. The maximum average relative humidity in wet months is 90%, and the average minimum temperature for that month is +25°C. Condensation on the product surface due to temperature fluctuations must be considered. If the temperature exceeds these limits, the user must consult with the user.

Protection Grade: IP30

Usage Category:Class B or Class A

Installation Category

Circuit breakers and undervoltage releases with a rated operating voltage of 660V (690V) or less, and the primary winding of the power transformer, are intended for installation category N; auxiliary circuits and control circuits are intended for installation category III.

Installation Conditions

Circuit breakers must be installed in accordance with the requirements of this manual. The vertical tilt of the circuit breaker must not exceed 5° (mining circuit breakers must not exceed 15°).

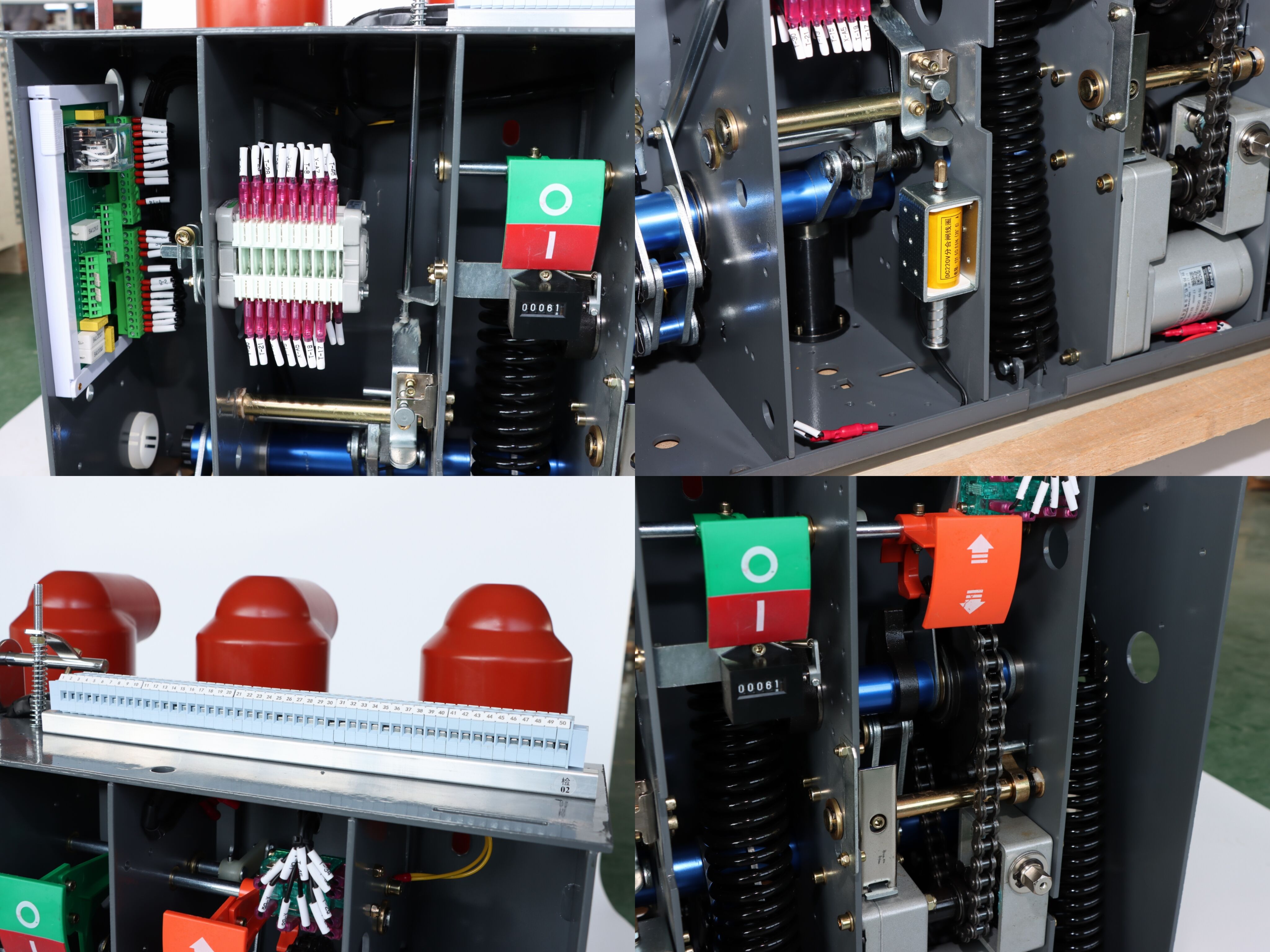

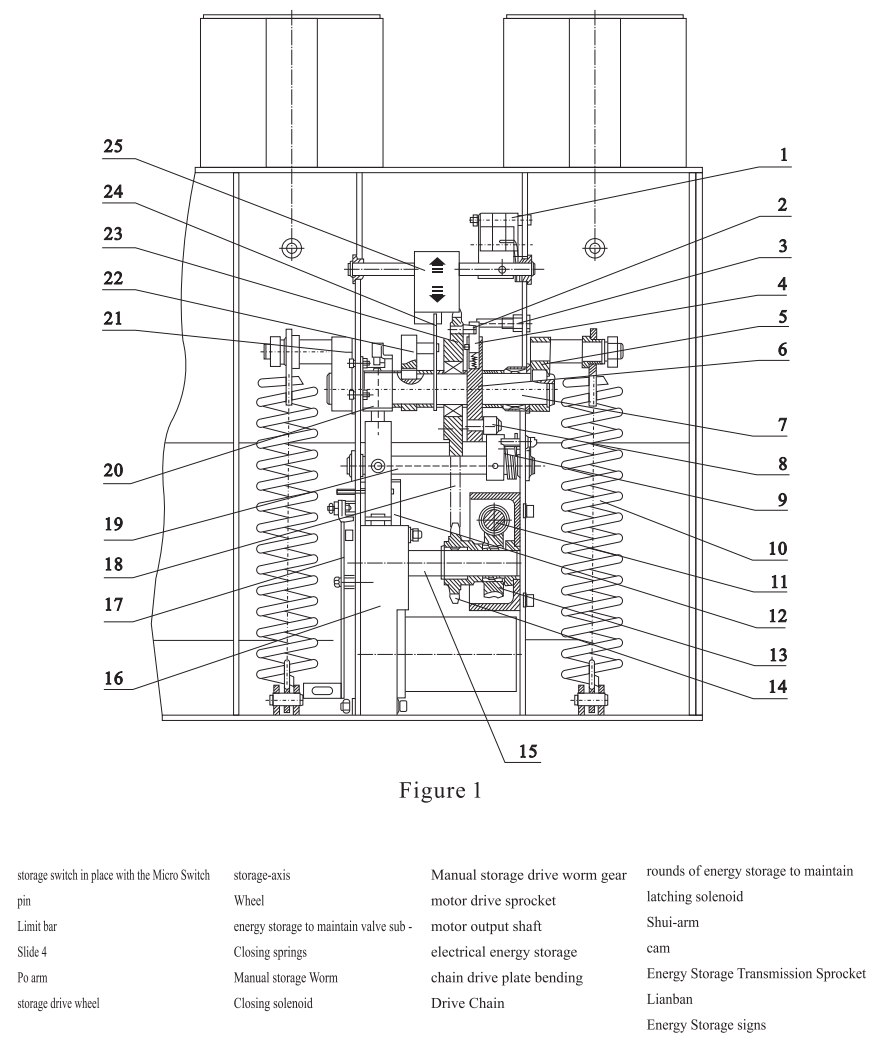

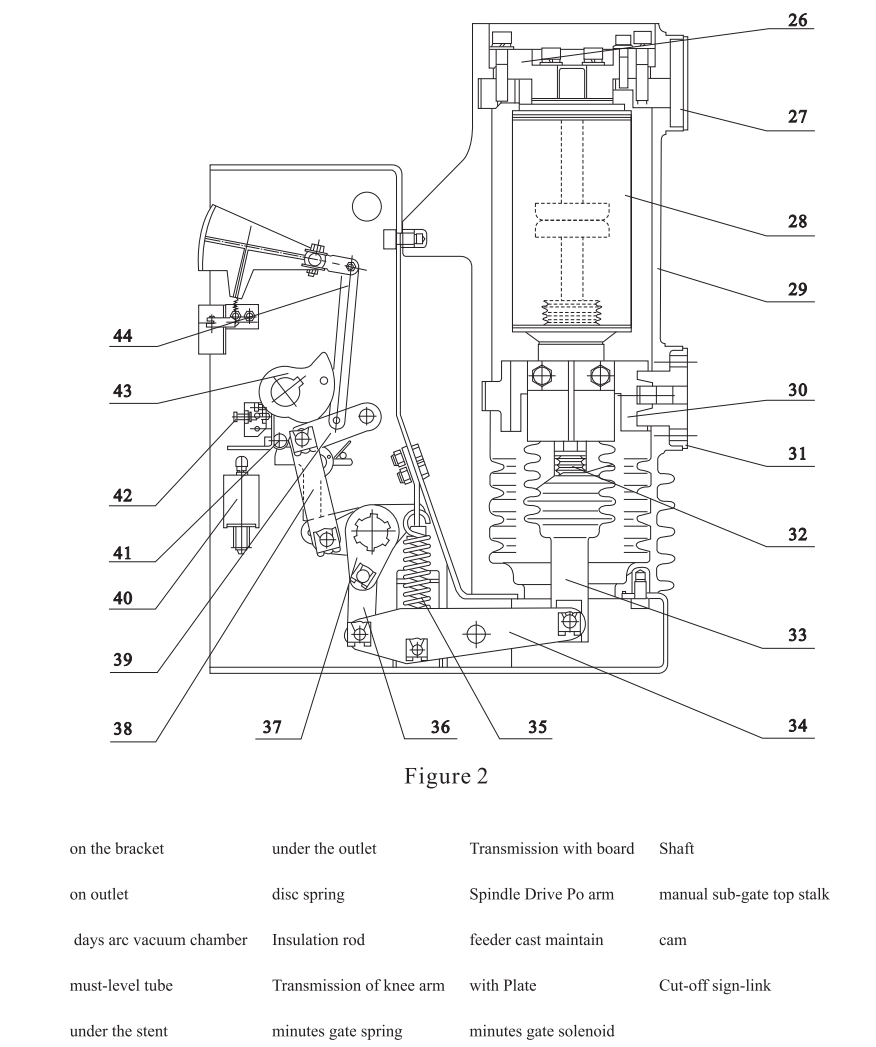

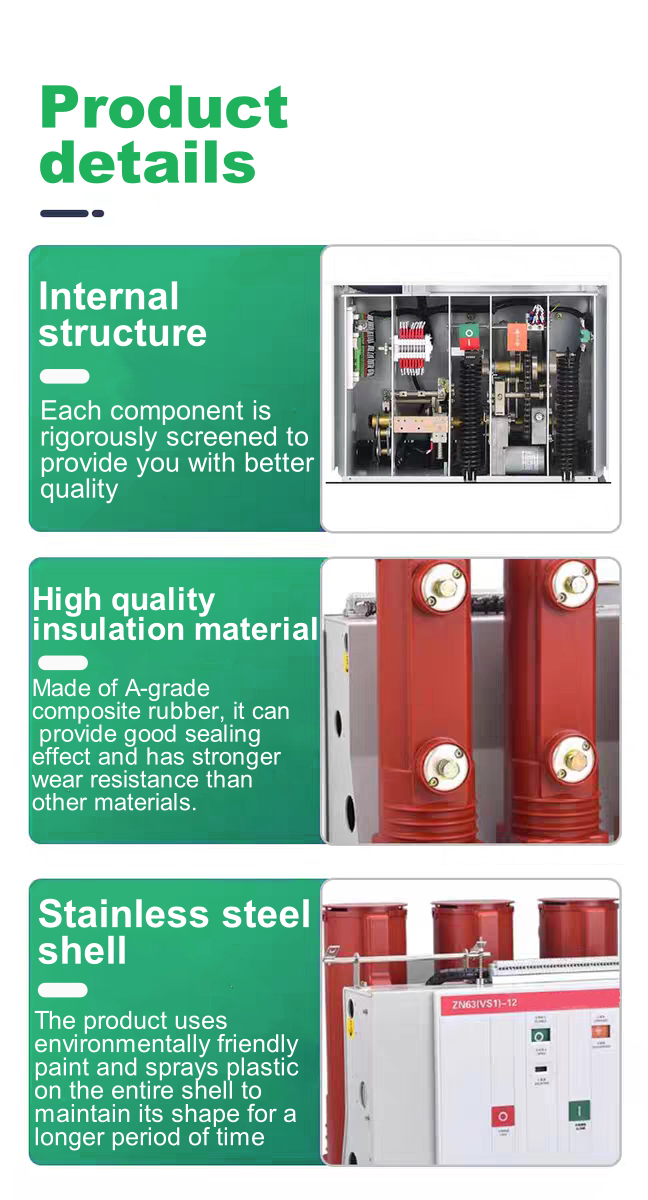

Internal component details

|

Internal constitutions:

Operating Mechanism→ Mechanical device controlling the opening and closing of the circuit breaker

Terminals (Fixed Type) → Electrical interface for fixed connections

Vacuum Interrupter → Core arc-extinguishing component containing contacts and ceramic insulator

Contact Arm (Drawout Type)→ Movable current-carrying component in drawout circuit breakers

Silver-Plated Copper Contacts→ Enhances conductivity and oxidation resistance

Drawout Chassis→ Frame structure supporting the movable parts of drawout circuit breakers

Insulating Cylinder→ Insulating housing encapsulating the vacuum interrupter

Aviation Connector→ High-reliability quick-disconnect interface

Finger Cluster Contacts→ Multi-finger contact design ensuring stable electrical connectio

|

|

Internal parts

|

Product quality

Quality of important components of the product

|

Vacuum arc extinguishing chamber (vacuum tube)

Dynamic and Static Contact: Located inside, made of special materials such as copper chromium alloy, it can maintain performance at high arc temperatures and has low current cutoff value. Shielding cover: an internal key component used to uniformly apply an electric field, absorb metal vapor generated by an arc, and protect the insulation shell from contamination. |

|

|

|

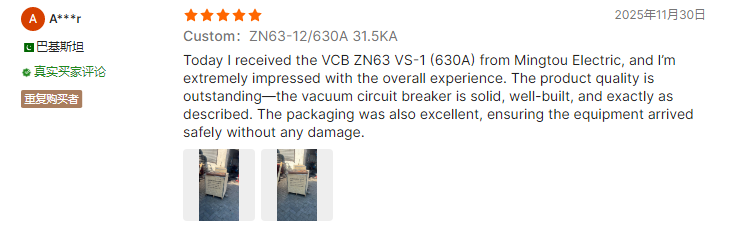

insulating cylinder

High insulation strength: able to withstand power frequency withstand voltage and impulse voltage far higher than the system voltage for a long time High mechanical performance: able to withstand huge push, pull, and impact during the opening and closing process without deformation or fracture. High dimensional stability: not easily deformed by temperature and humidity, ensuring transmission accuracy and stroke stability.

|

|

|

Quality Details

|

|

Product Installation

Product application scenarios

Core protection of power generation, transmission, and distribution networks

Power plant: protect the generator outlet and the plant power system.

Substation (core application scenario): Installed in 10kV to 35kV (medium voltage) distribution substations, it serves as a protection and control switch for key equipment such as outgoing lines, busbars, capacitors, and transformers. In the event of system faults such as short circuits, it can cut off the fault current in milliseconds.

The 'gateway' for industrial and commercial users

As the main switch for the main incoming cabinet, contact cabinet, and feeder cabinet in high-voltage distribution rooms of factories, large buildings, data centers, and hospitals. Responsible for the input and output of normal power supply, and quickly tripping in case of internal faults within the user to prevent the accident from escalating.

Frequent operation and special load control

Capacitor bank switching: Due to its good breaking capacitive current performance and long lifespan, it is very suitable for frequent switching operations of reactive power compensation capacitors.

Motor control: used to control the start and stop of large high-voltage motors.

|

|

|

Production line

Factory real shooting

|

|

|

|

|

Product testing

1、 Mechanical characteristic testing (verifying mechanical action performance)

Travel - Overtravel Test:

Total travel Overtravel Open distance test

2、 Electrical performance testing (verifying current carrying and breaking capacity)Circuit resistance test:

Apply a direct current (usually 100A) to the circuit breaker and measure the milliohm resistance of its main circuit (including contacts). The resistance value must be extremely low and stable, otherwise it will cause abnormal heating during operation.

High current test (temperature rise and dynamic thermal stability):

Temperature rise test

Dynamic/Thermal Stability Test

Overload and opening/closing operation test:

Overload test Opening and closing operation test

3、 Insulation and protection function testVoltage withstand test (insulation strength verification):

Power frequency withstand voltage

Impulse withstand voltage

Protection function and auxiliary characteristic testing

Undervoltage trip test

Bounce test

|

|

|

|

|

Packaging

|

|

|

Outer packaging:

Strong wooden boxes are usually used to provide sufficient mechanical strength.

Wooden crate suitable for large circuit breakers or international transportation

Inner packaging:

Wrap the circuit breaker with buffer materials such as foam pad, bubble film or pearl cotton to prevent vibration and collision.

For large circuit breakers, the packaging box may adopt a layered design, with accessories (such as manuals, tools, spare parts) placed on the upper layer

Upgraded Packaging

|

Strengthening of cover plate structure

Add support columns at the edges

Overall load-bearing performance improvement

|

|

|

|

Domestic transportation

If there is a designated freight forwarder in china, we willtransport the products to the designated location through road transportation or domestic express delivery after production is completed

International transport

When the quantity of goods is small and time is tight, and it needs to be transported to a designated location abroad, the three majorinternational express delivery companies are selected for transportation DHL,FEDEX,UPS

Sea freight/air freight

When there is a large quantity of goods and time is not urgent, we choose sea freight. We will choose a suitable freight company, who wil arrange for trucks to pick up the goods and transport them to the designated por for warehousing. Finaly, they will transpored by sea to the customer's desianated port, and the customer needs to pick up the goods with a bill of lading.

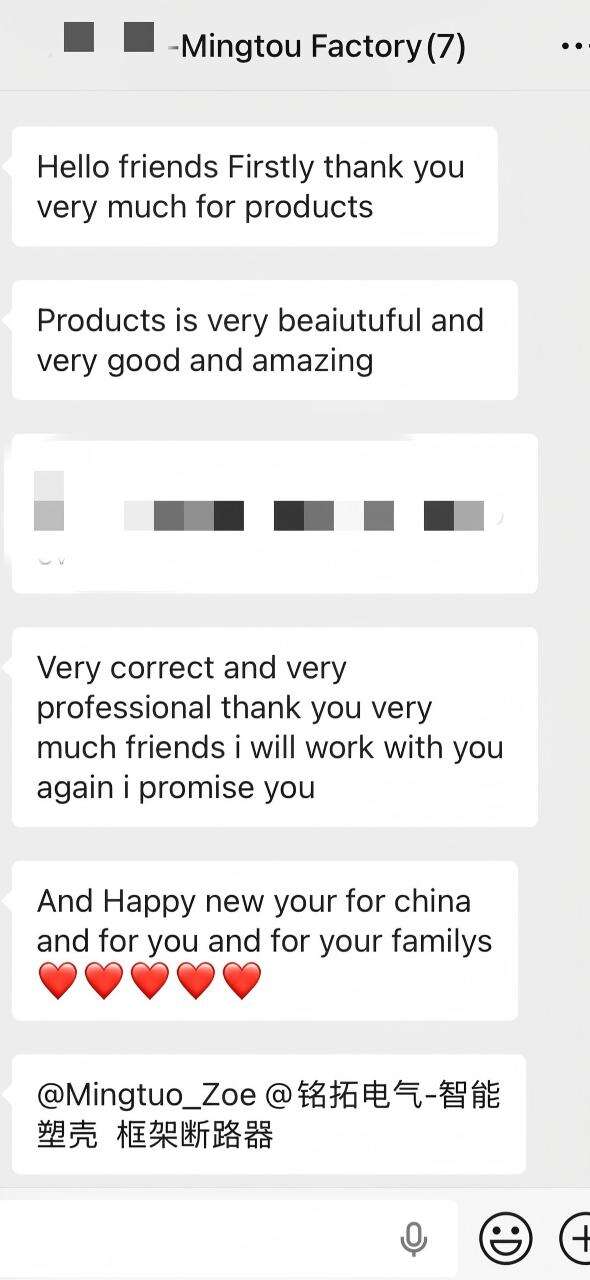

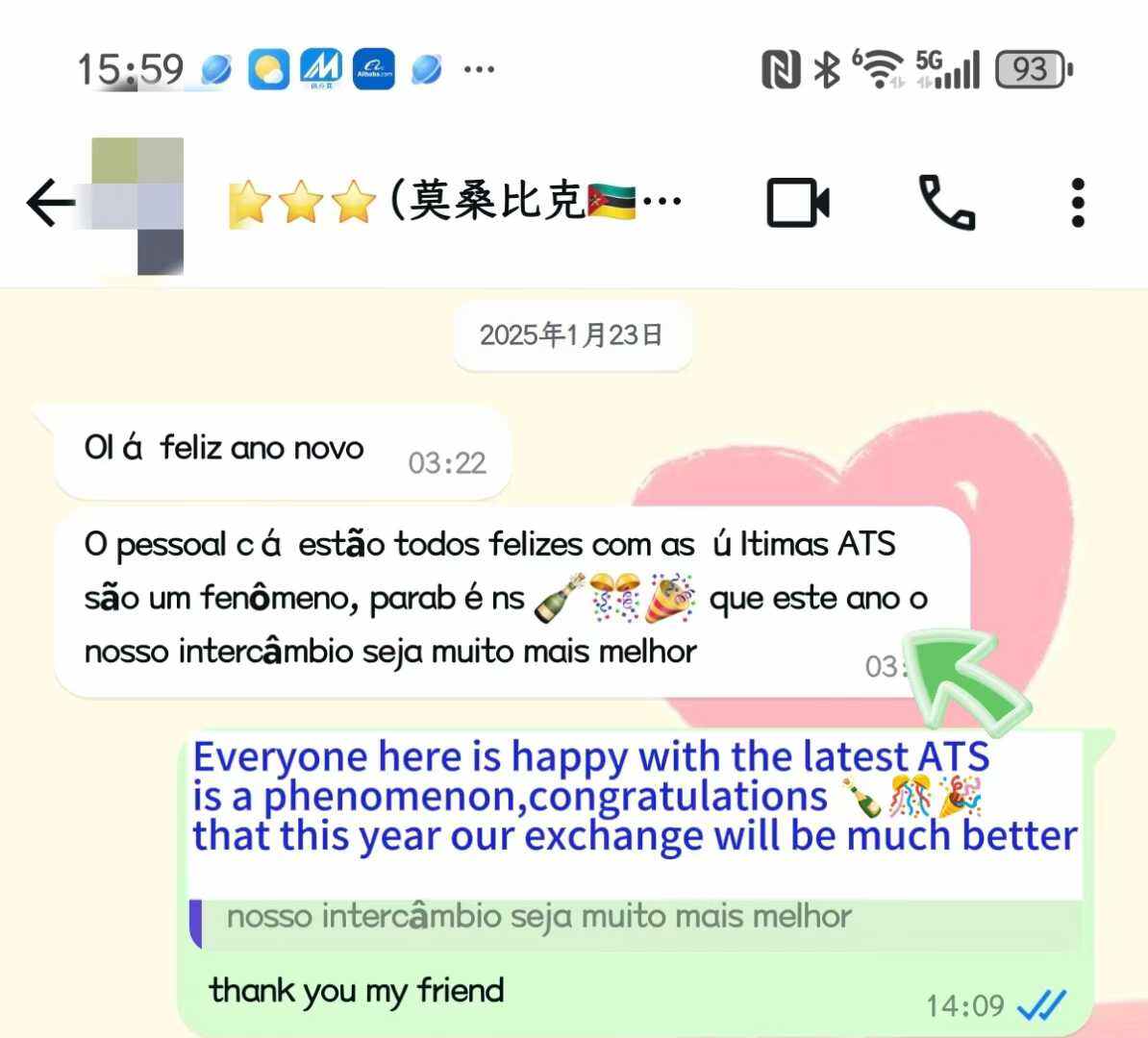

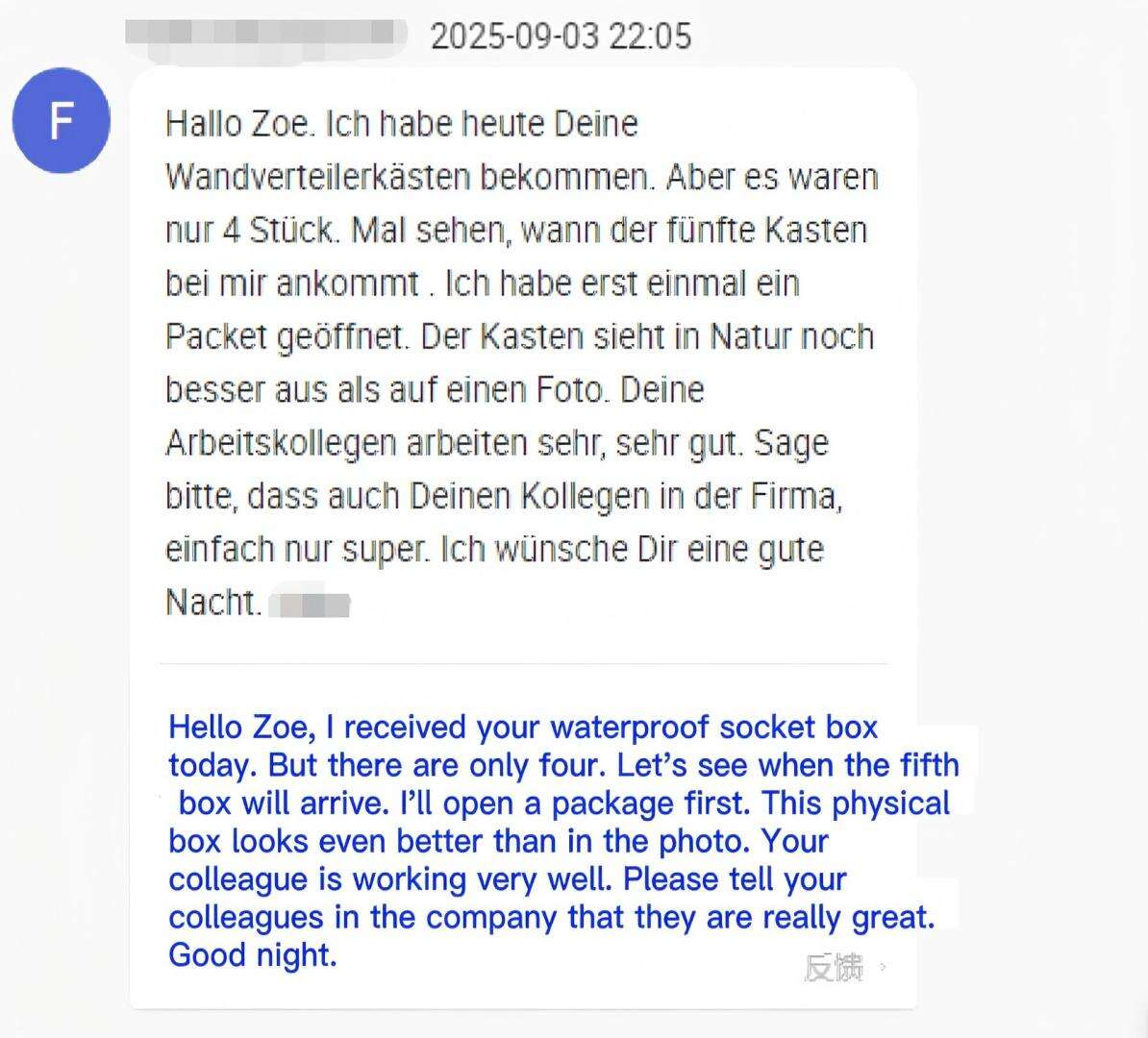

Customer feedback

|

|

|

|

|

|

|

|

|

|

|

|

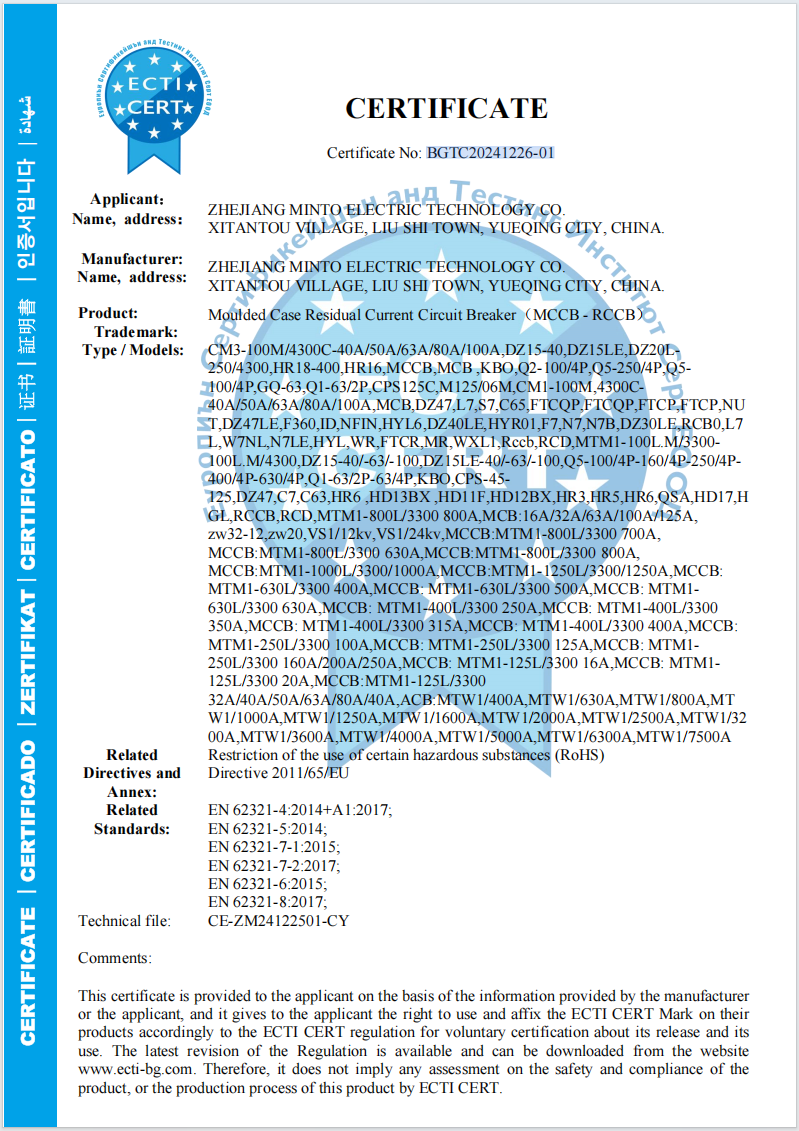

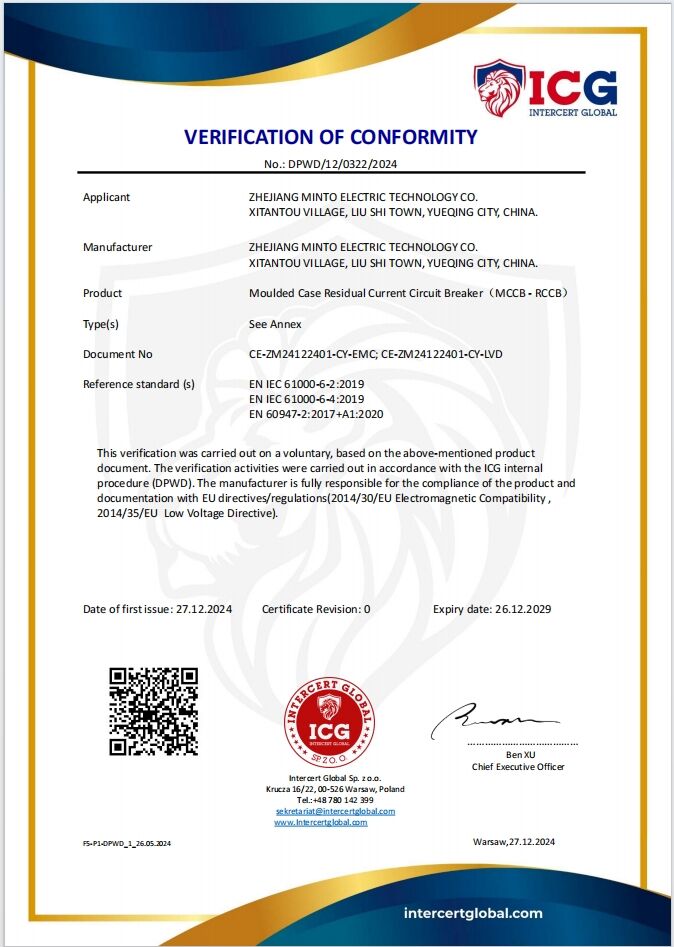

Certificate

|

|

|

FAQ

Q: What is the voltage/current range of this product? What is its breaking capacity?

A: Please contact customer service for details.

Q: What is the minimum order quantity? Do you accept sample orders?

A: The minimum order quantity is 1 set, and we accept sample orders.

Q: What is the warranty period? How do I apply for a warranty?

A: The product warranty is 1 to 2 years. Please contact customer service directly to apply.

Q: Do you have CE, RoHS, UL, or other certifications? Can you provide certificates?

A: We have CE and RoHS certifications and can provide certificates.

Q: Does the price include tax/shipping?

A: The price does not include shipping/tax.

Q: What notable clients or project examples have you worked with?

A: State Grid Corporation of China, Chint Group.