CONTACTOR

Product description

AC contactor is an electrical control device widely used in automation control systems for remote connection and disconnection of AC power circuits. It mainly consists of an electromagnetic system, a contact system, an arc extinguishing device, and auxiliary components.

When the electromagnetic system is powered on, the generated magnetic field will attract the contacts to close, thereby connecting the circuit;

When the power is cut off, the magnetic field disappears, and the contacts separate by spring force or other mechanical devices, disconnecting the circuit.

The MINGTUO LC1D AC Contactor Series provides switching that is reliable and efficient for various control and protection applications of AC. Using high-quality components of an electromagnet and contacts that are wear-resistant, the contactors keep very good electrical performance even after a long service life. Their small design and modular accessory layout allow them to be the perfect solution for integration into industrial machines, control cabinets, and automated systems.

Working principle:

|

Working principle:

The working principle of an AC contactor is based on electromagnetic effects, and its core function is to control the power on and off of the electromagnetic coil to achieve the closure and disconnection of the main contact, thereby controlling the connection and disconnection of the load circuit.

AC contactors are usually equipped with auxiliary contacts for control or signal transmission. Auxiliary contacts can be of the normally open (NO) or normally closed (NC) type, which change state with the action of the main contact and are used to achieve interlocking, signal indication, or other control functions.

|

General Product Information

- Place of Origin: 5th Floor, No. 3 Jinghong West Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province

- Brand Name: MINGTUO

- Model Number: AC Contactors

- Certification: ISO, CE, RoHS

Commercial Terms

Specification Details:

Minimum Order: Quantity 1

Price:USD 3-9

Packaging:Carton

Delivery Time:Within 15 days

Payment Terms:100% Prepaid / 70%-30% / 80%-20%

Supply Ability:Ready to ship

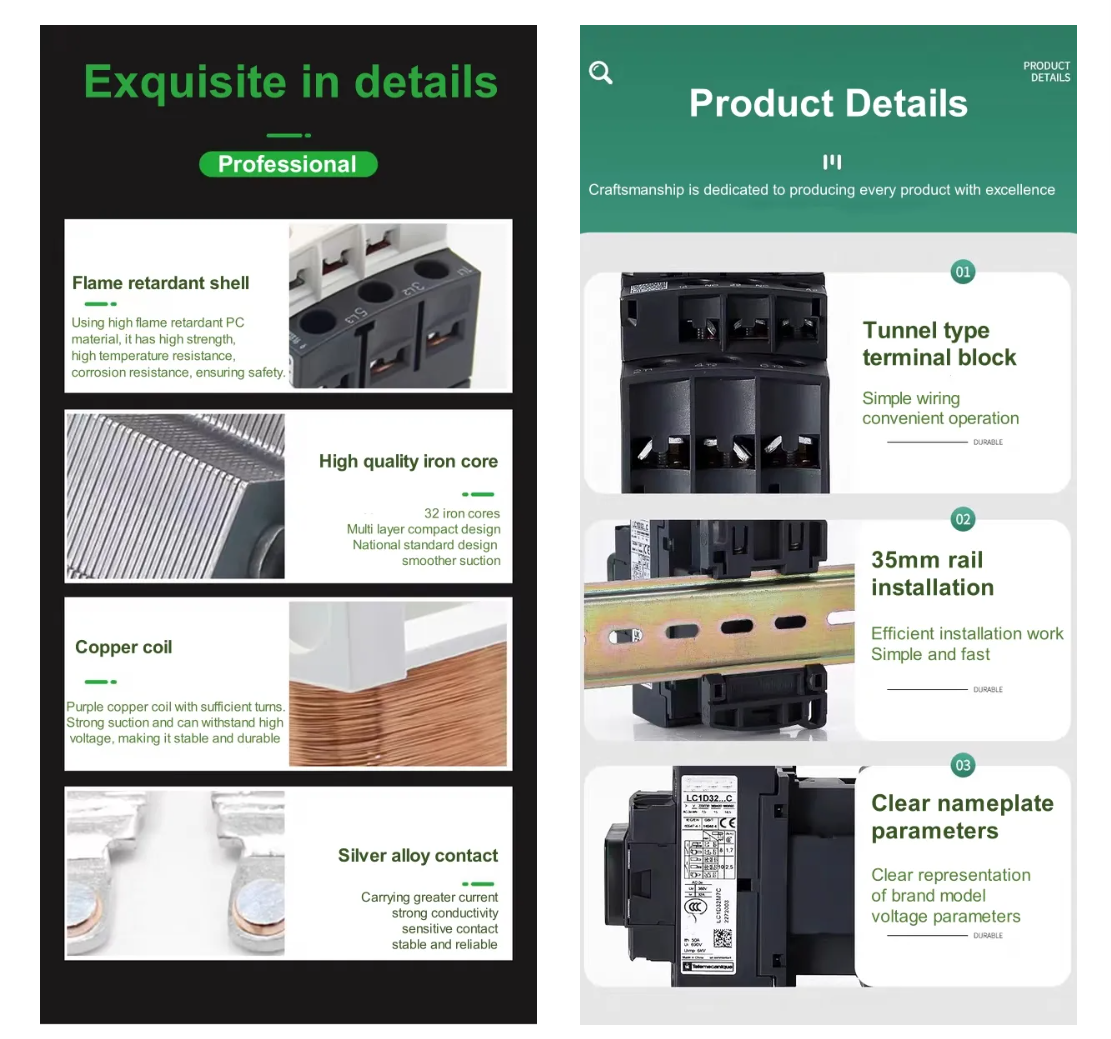

Core technological advantages

High electrical and mechanical lifespan

- Using high-quality silver alloy contacts, it is arc resistant, wear-resistant, and has an electrical lifespan of over one million cycles.

- The mechanical structure is sturdy, with up to tens of millions of movements, suitable for frequent start stop scenarios.

Energy saving and low heat design

- Low power consumption of the coil, energy-saving design (such as AC coil with energy-saving circuit).

- The contact pressure is reduced, the heat generation is small, and the power loss is minimized.

safety and reliability

- Compliant with international safety certifications such as CCC, CE, UL, etc.

- The arc extinguishing system is efficient, has strong breaking ability, and is resistant to short-circuit current impact.

- Good insulation performance, dust-proof and anti electric shock design.

Intelligence and modularity

- Can integrate accessories such as auxiliary contacts, delay modules, mechanical interlocks, etc.

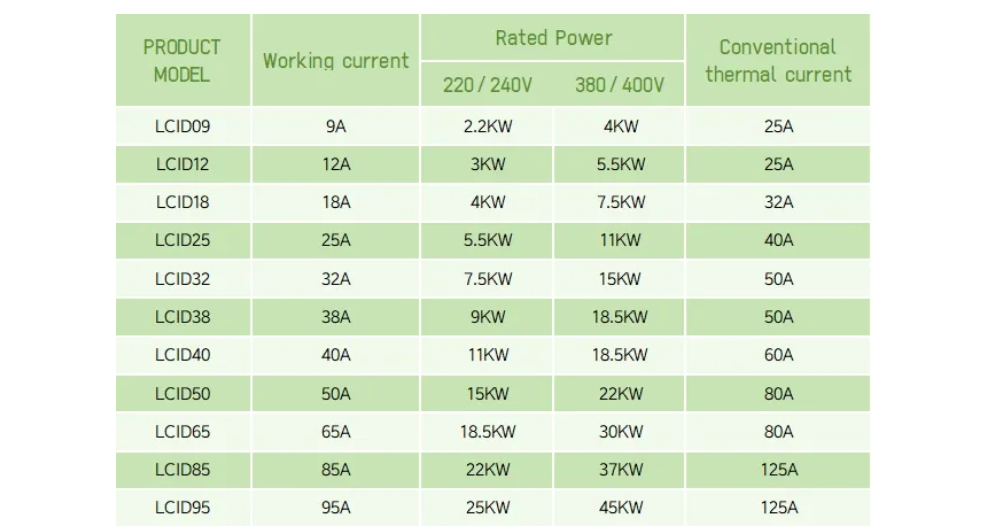

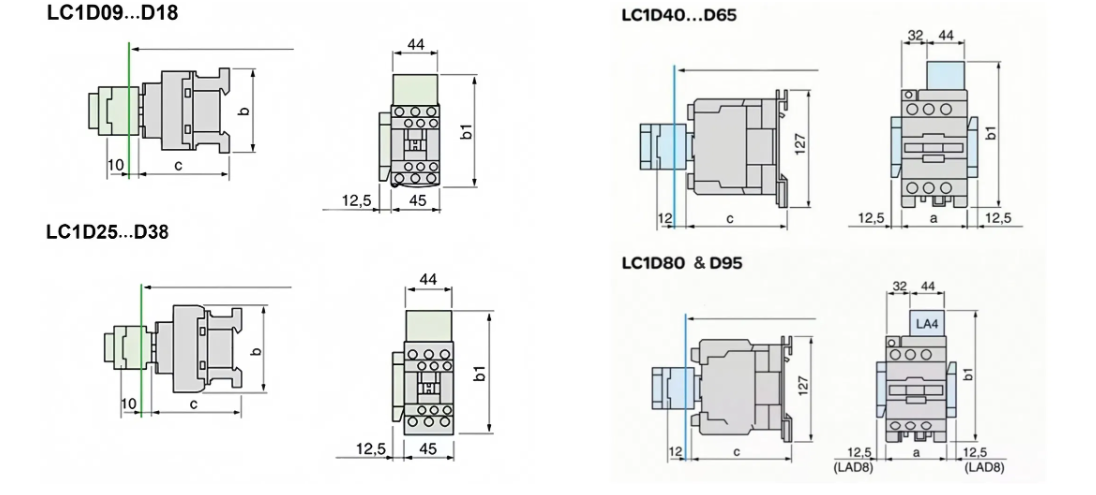

Key specifications

| Rated Current |

9A–95A |

Control Voltage |

AC/DC 24V–500V |

| Rated Operating Voltage |

AC 220V / 380V / 660V |

Mechanical Life |

10–30 million cycles |

| Pole Options |

3-Pole / 4-Pole |

Electrical Life |

1–3 million cycles |

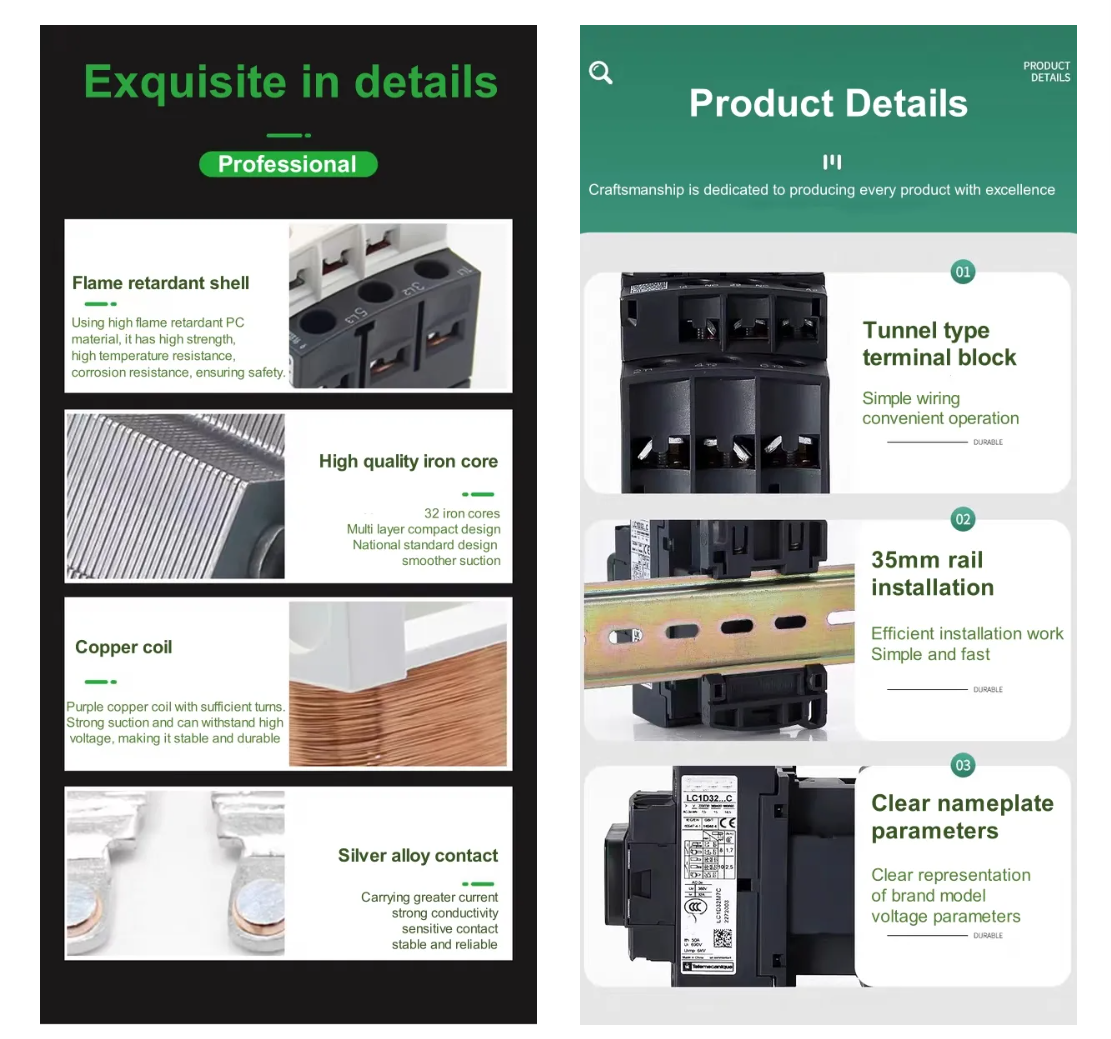

Technical Features

- Coil for the electromagnet which is energy saving

- Contact points are made of a high conductivity silver alloy

- Designed to be fully supported with auxiliary accessories

- Mounting can either be 35mm DIN-rail or by screw

- High electrical life and a strong break capacity

- A modular design that saves space and allows for small panels

Main Applications

Motor Control

- Start/stop operations for three-phase motors

- Forward/reverse control circuits

- Pumps, compressors, conveyors

- Industrial machinery and mechanical drives

HVAC & Environmental Systems

- Air conditioning compressors

- Ventilation and cooling fans

- Heating equipment control

- Chillers and AHU units

Industrial Automation

- Automated production equipment

- PLC and control system integration

- Robotics and process control

- Assembly line power management

Power Distribution

- Lighting circuit control

- Heating element switching

- Capacitor bank and transformer switching

- Power factor correction systems

Specialized Applications

- Elevators, cranes, and hoists

- Welding machines

- Data center power routing

- Renewable energy equipment

Quality Assurance

All the AC contactors are built to conform to IEC 60947-4-1 standards. Various quality checks are done on each unit, some of them being:

- Electrical endurance tests

- Coil heating and temperature rise measurement

- Performance verification under load

- Insulation and dielectric strength testing

- Mechanical reliability checks

Service Support

- A large range of auxiliary modules and add-on accessories

- Documents of international certification

- 2 years warranty for all models

- Complete product manuals

- Custom configurations available upon request

Quick Detail Keywords

- AC Contactor

- Electrical Contactor

- Magnetic Contactor

- Motor Contactor

- Power Contactor

- Electromagnetic Switch

- Industrial Contactor

- 3-Pole/4-Pole Contactor

- 40A AC Contactor

- 380V Contactor

- Power Relay

- Motor Control Switch

- Heavy Duty Contactor

- Industrial Power Controller

AC Contactor — Core Functions & Usage Scenarios

AC contactors are the key elements in power control systems that enable remote and automated switching of high-power loads by low-power control circuits. Due to their quick reaction, long service life, and safe separation capability, they are the perfect choice for those applications which require frequent switching and reliable protection.

Main Benefits

- High-current circuits controlled in a safe way

- Electrical isolation between control and power circuits

- Ability to be switched at high frequency

- Automation and control wiring made simple

- Overall equipment safety and lifespan enhanced