лиушы қаласы, Юйцюань қаласы, Цзиньхунға Батыс көшесі, №3, 5-қабат, Чжэцзян провинциясы, Вэньчжоу +86-13057710980 +86-18334450116 [email protected]

Суға төзімді розетка қорапшасы

Металл түрі

|

|

|

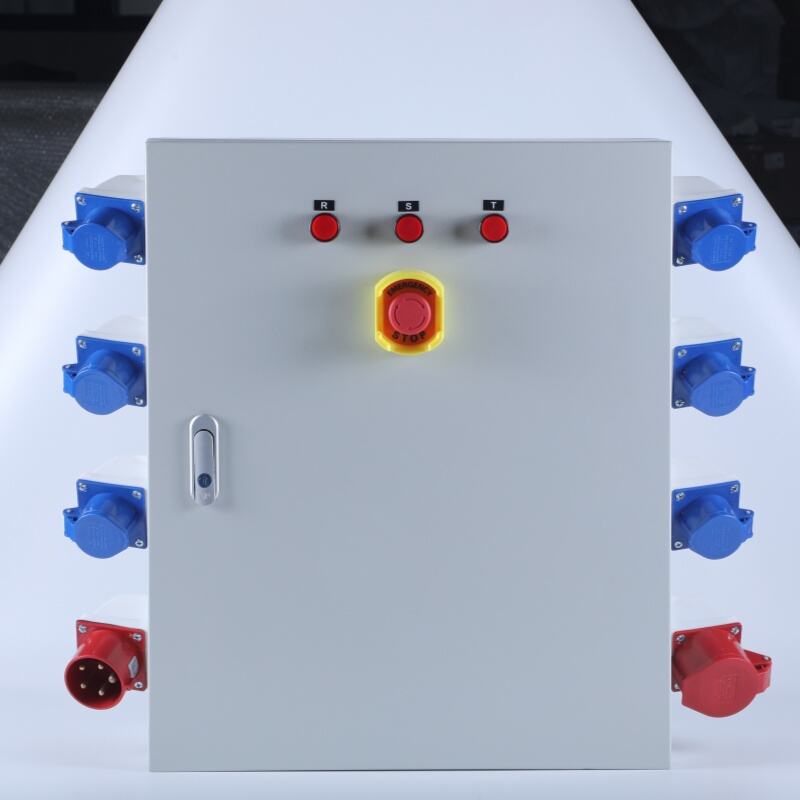

Металл суға төзімді розетка қорапшасы: өнеркәсіптік қорғаныс, тастай берік

Ең қатаң өнеркәсіптік орталарға бейімделу үшін туылған, біздің металл суға төзімді розетка қорапшамыз берік қорғанысты, өте жақсы герметизациялауды және икемді қуат конфигурациясын үйлестіреді және құрылғылардың үздіксіз қуатын және қауіпсіз жұмыс істеуін қамтамасыз етуге надежды негіз болып табылады.

Негізгі плюслер:

Әскери сападағы қорғаныс, шабуылдардан тәуелсіз: өте берік цинкпен капталған болат немесе алюминий қорытпасының қаңқасын пайдалану арқылы құрылымы мықты, соққыға және коррозияға төзімді. Қорғаныс деңгейі IP65/IP66/IP67-ге дейін жетеді, толықтай шаңнан қорғалған және жоғары қысымдағы су ағынының шайылуына немесе қысқа мерзімді суға малынуға шыдайды. Ылғалды, шаңды, майлы және соқтығысуға бейім сыртта, құрылыс алаңдарында, зауыттарда, пристаньдарда сияқты күрделі орталарда оңай бағаға келеді.

Герметизациялаудағы шеберлік, тамшыламайды: Қорап денесі мен қақпақ арасында жоғары сапалы силиконды тығындайтын сақиналар қолданылады, көп нүктелі блоктау немесе бұрандалы бекіту конструкциясымен үйлестіріліп, толықтай сығылымды тығындайтын жүйе қамтамасыз етіледі. Кіріс пен шығыс әдетте су өткізбейтін гильза басымен жабдықталған, осылайша толық тығыздандыру және қорғау жүйесі құрылады.

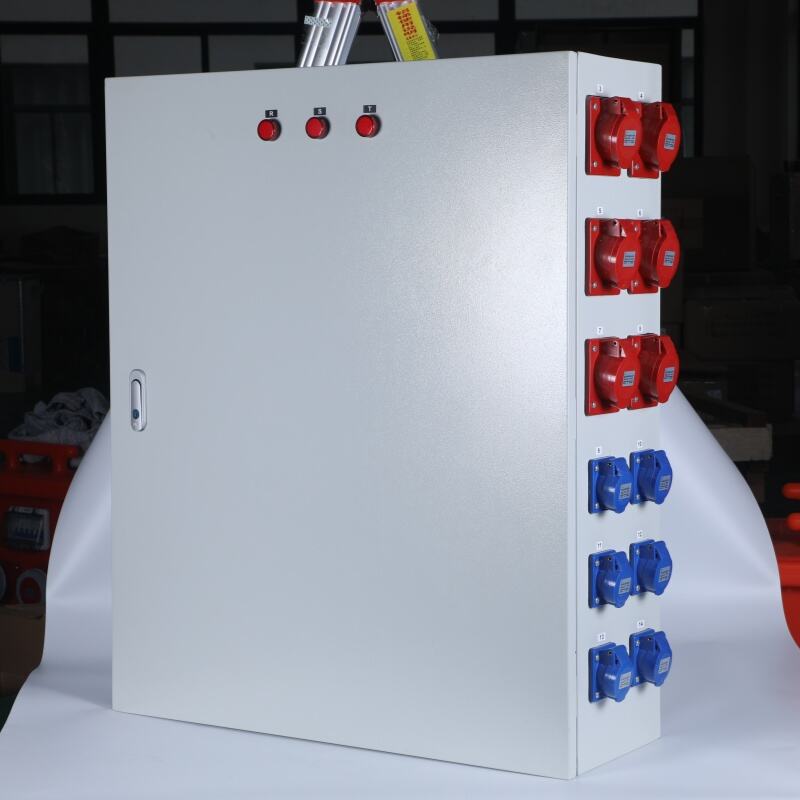

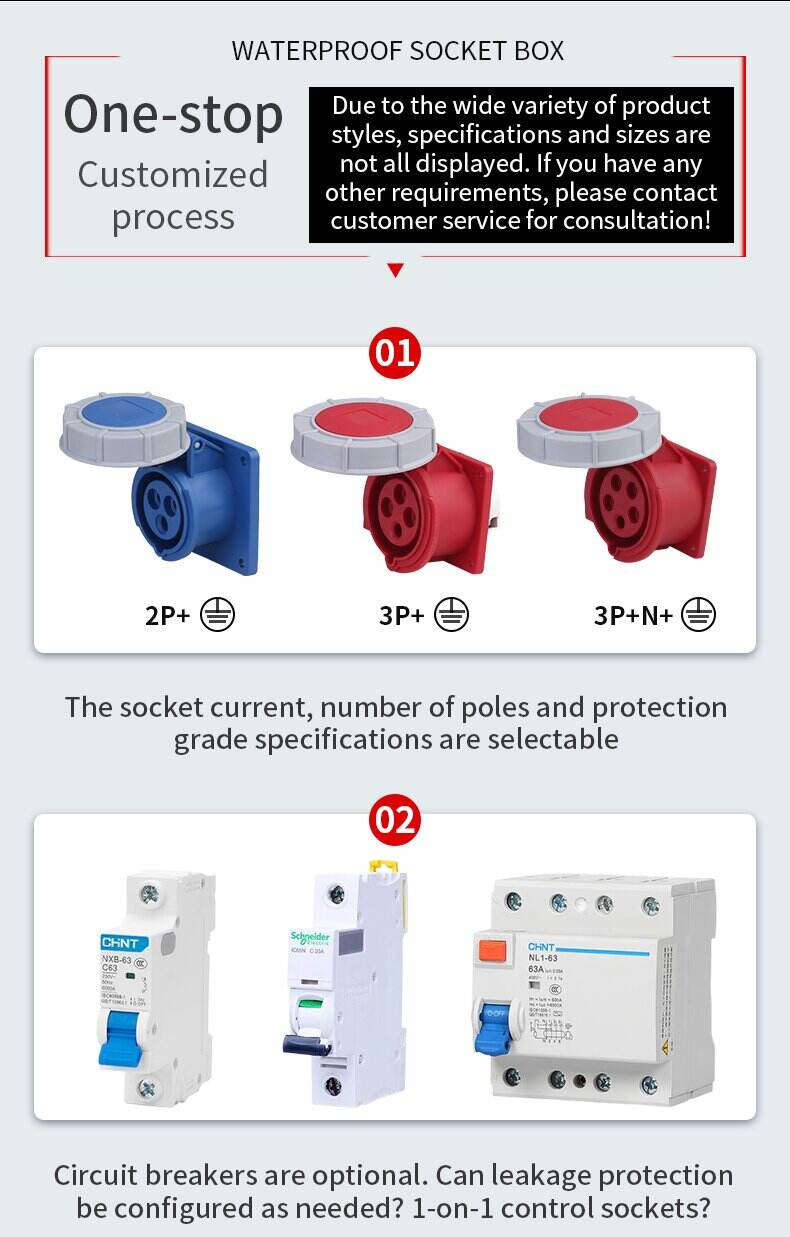

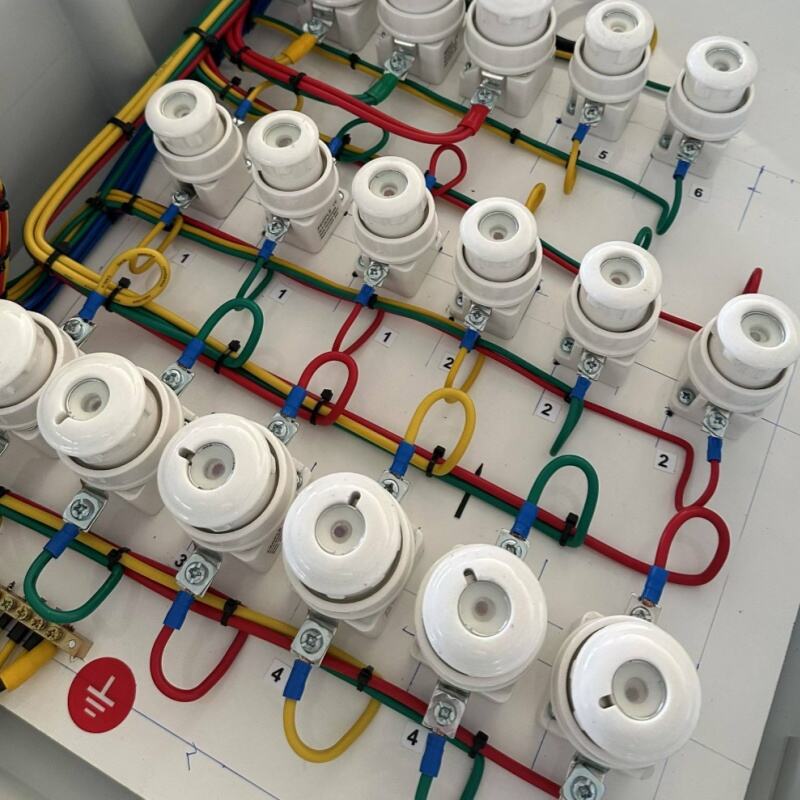

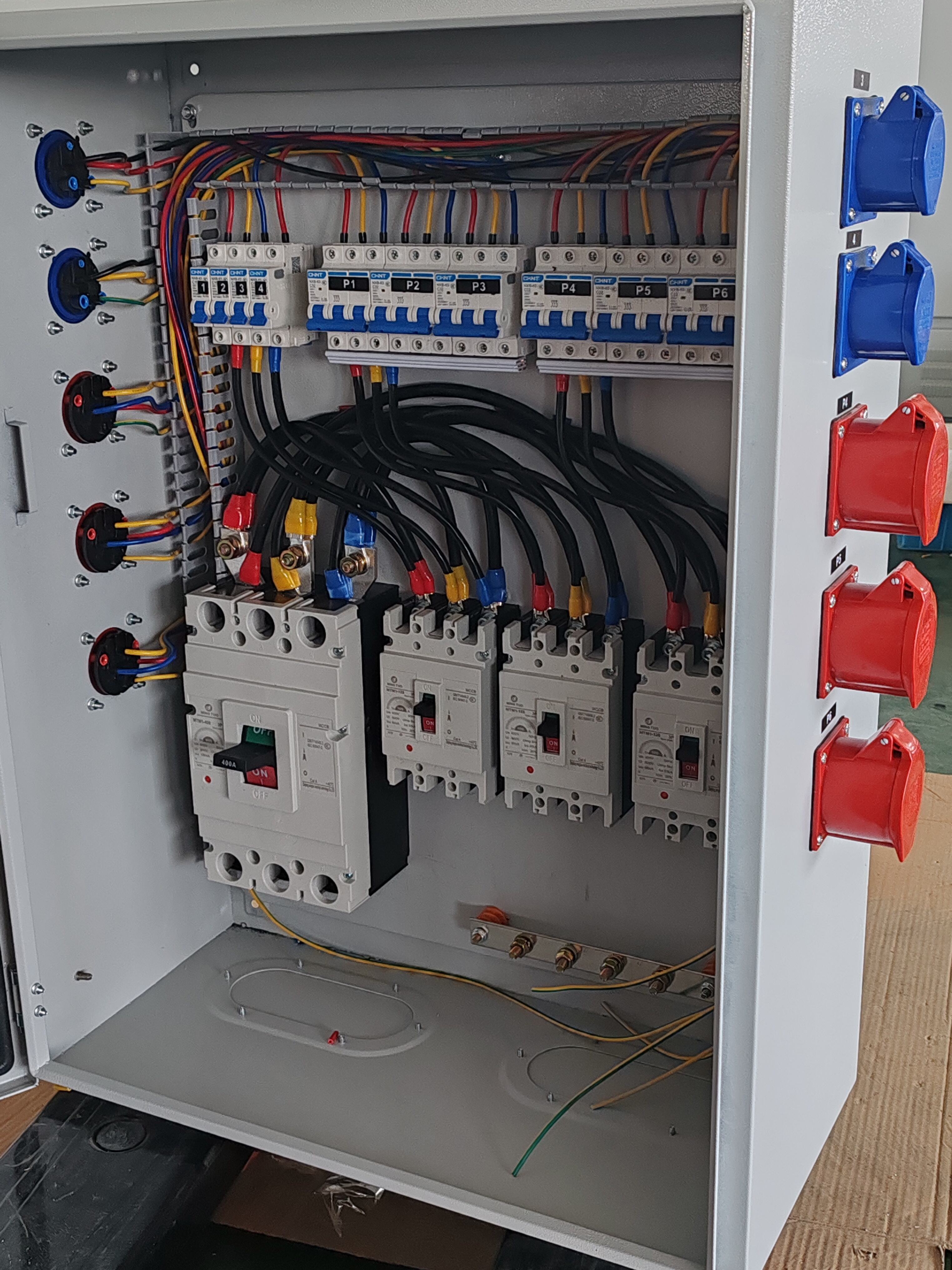

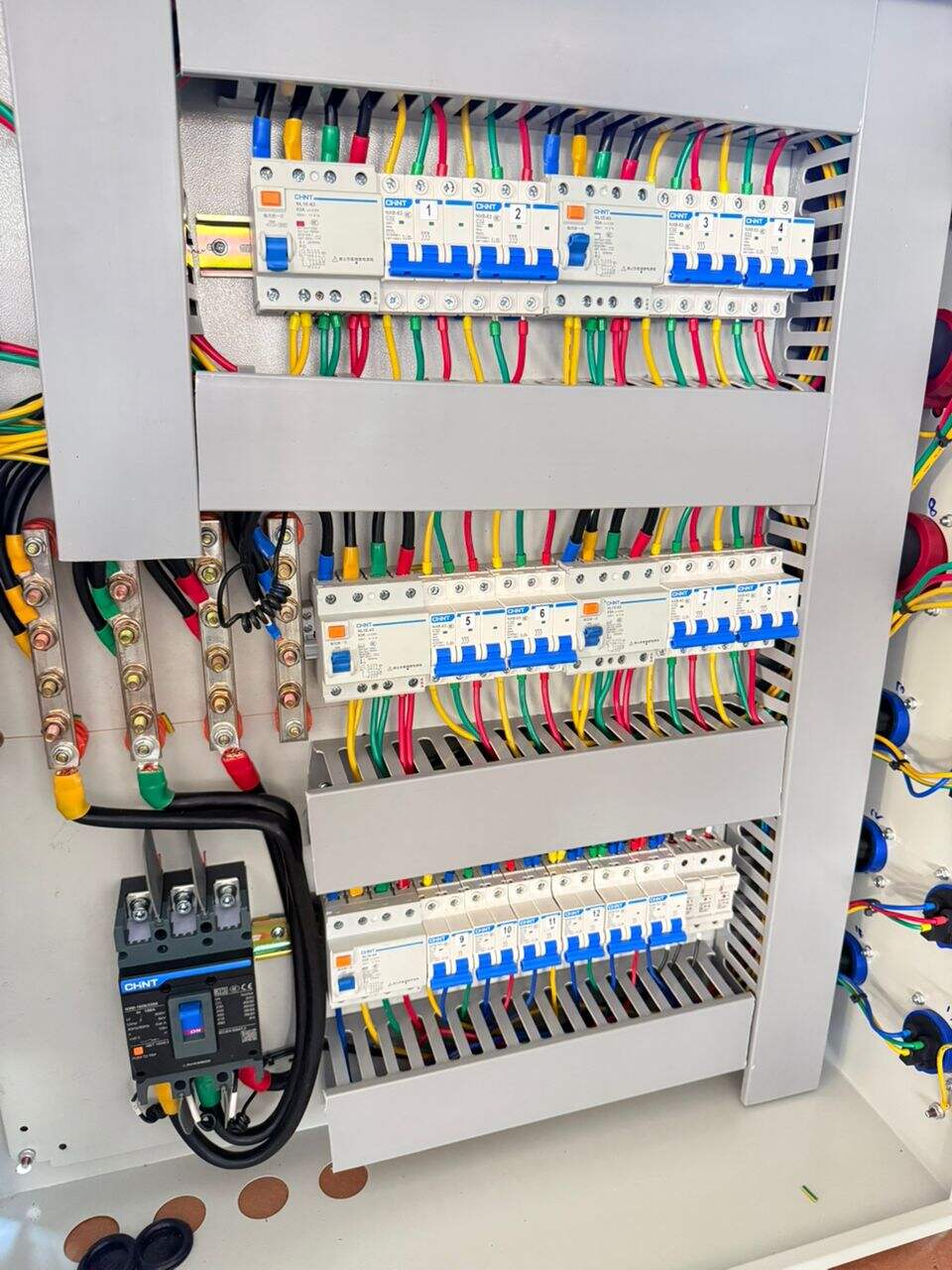

Модульді конфигурация, электр қуатының негізгі бөлігін икемді анықтау: Ішкі жағынан жоғары сапалы рельстермен жабдықталған, өнеркәсіптік розетка модульдерін (мысалы IP44/IP67 розеткалар), автоматты ажыратқыштар, бұқтырушылар, контакторлар сияқты құрылғыларды икемді орнатуға мүмкіндік береді, қуаттың дәстүрлі қамтамасыз етілуінен бастап құрылғыларды басқару мен сигналдарды беруге дейінгі көптеген функцияларды интеграциялау талаптарын қанағаттандырады. Бұл сіздің жеке компакттық тарату орталығыңыз.

Егжей-тегжейлі сипаттамалар кәсіби деңгейді көрсетеді:

Беті экологиялық таза электростатикалық бояумен қапталған, коррозияға төзімді, үйкелуге төзімді және тазалауға жеңіл.

Терезешелі құрылым (опциялық), жұмыс режимін бірден көзбен шолып бақылауға мүмкіндік береді.

Жабдықтардың идентификациялануы мен басқарылуын жеңілдету үшін шелк-скринті немесе тапсырыс бойынша жасалған белгілеуді (міндетті емес суға төзімді PVC/металл табелі) қолдау көрсетеді.

|

|

|

|

1-қадам: Негізгі электрлік сипаттамаларды анықтау

Розетка таңдау критерийлері:

Панельдің орналасуы:

2-қадам: Қорғаныс пен басқару құрылғыларын таңдаңыз

Ажыратқышты таңдау:

|

|

3-қадам: Корпустың дизайны мен соңғы орналасуы

Корпусты таңдау:

Суретті растау:

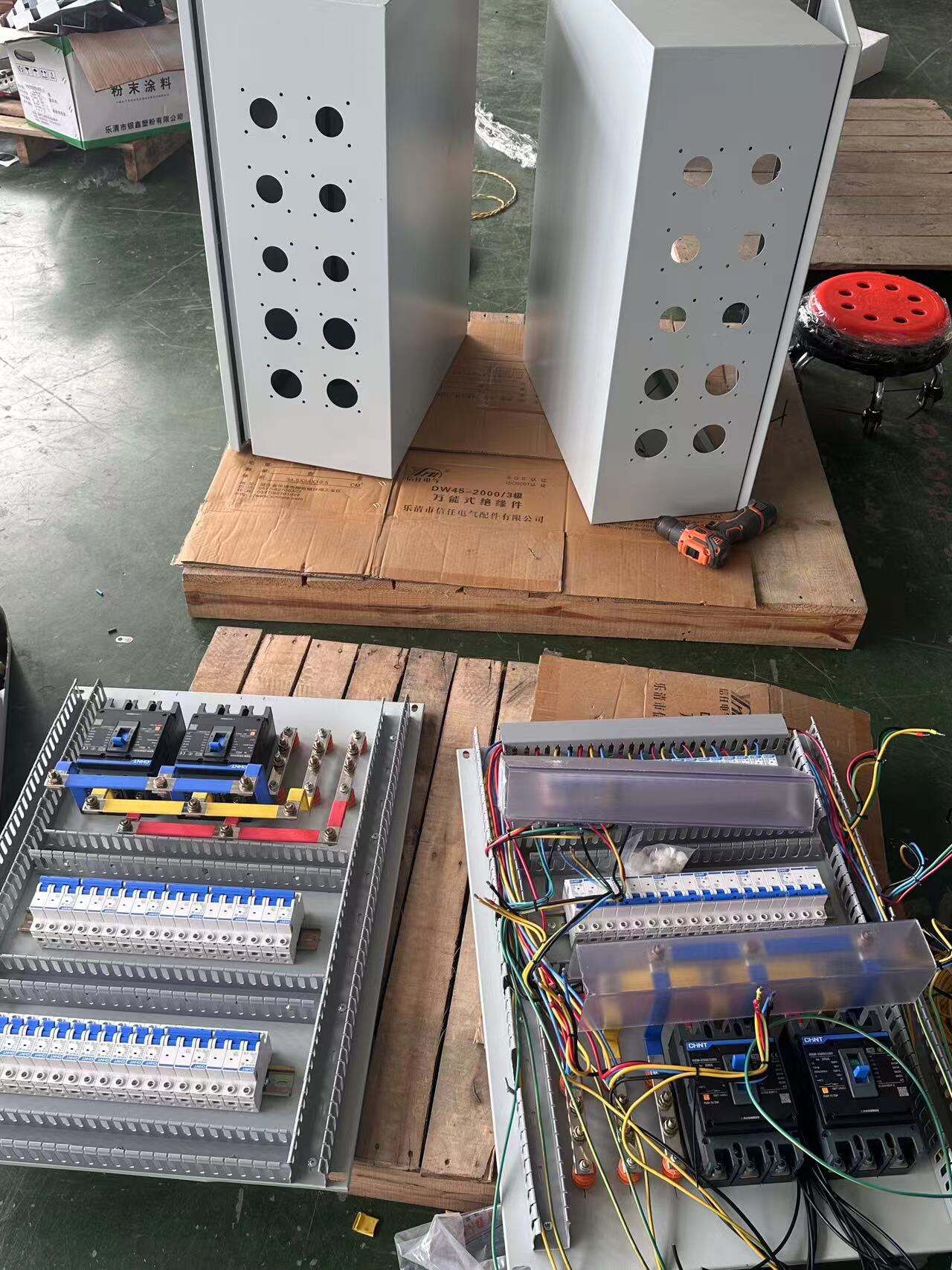

4-қадам: Өндіріс, сынақ және жеткізу

Құрылған:

Зауыттағы сынақ:

Жеткізу: |

Жалпы продукт туралы мәліметтер

Шығу орны: |

лиушы қаласы, Юйцюань қаласы, Цзиньхунға Батыс көшесі, №3, 5-қабат, Чжэцзян провинциясы, Вэньчжоу |

Бренд атауы: |

MINGTUO |

Модель нөмірі: |

өнеркәсіптік розетка қорапшасы |

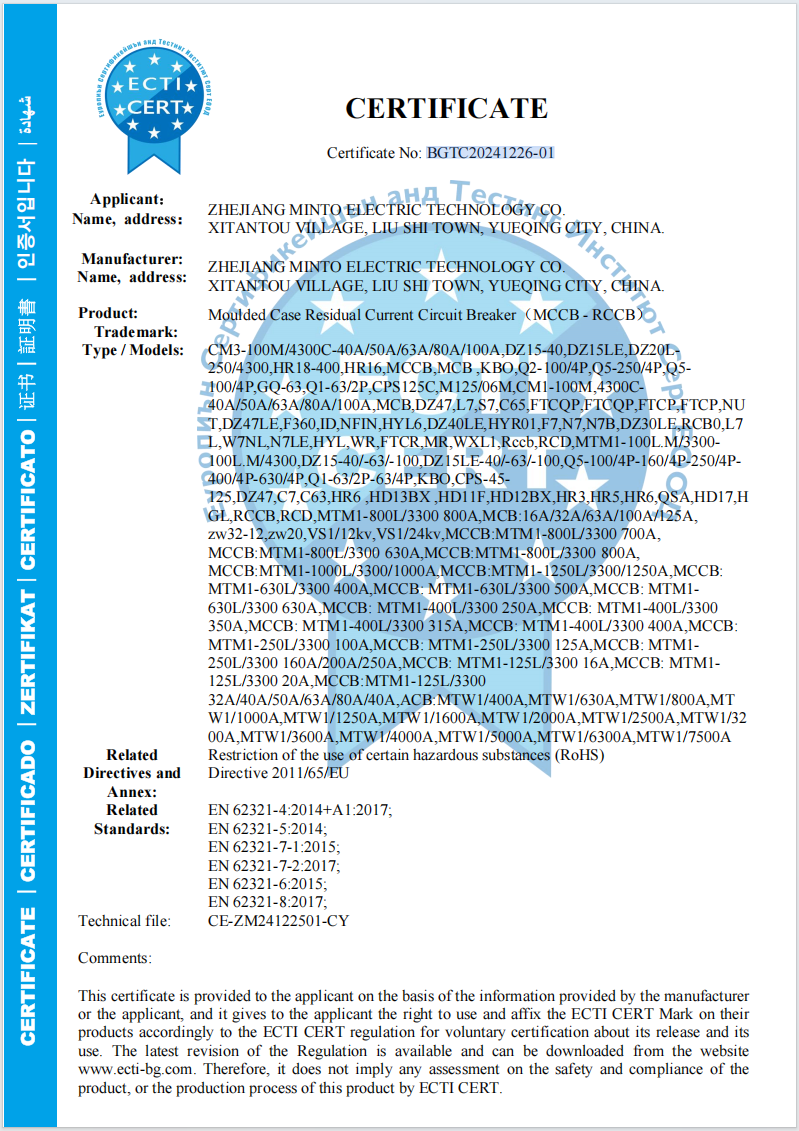

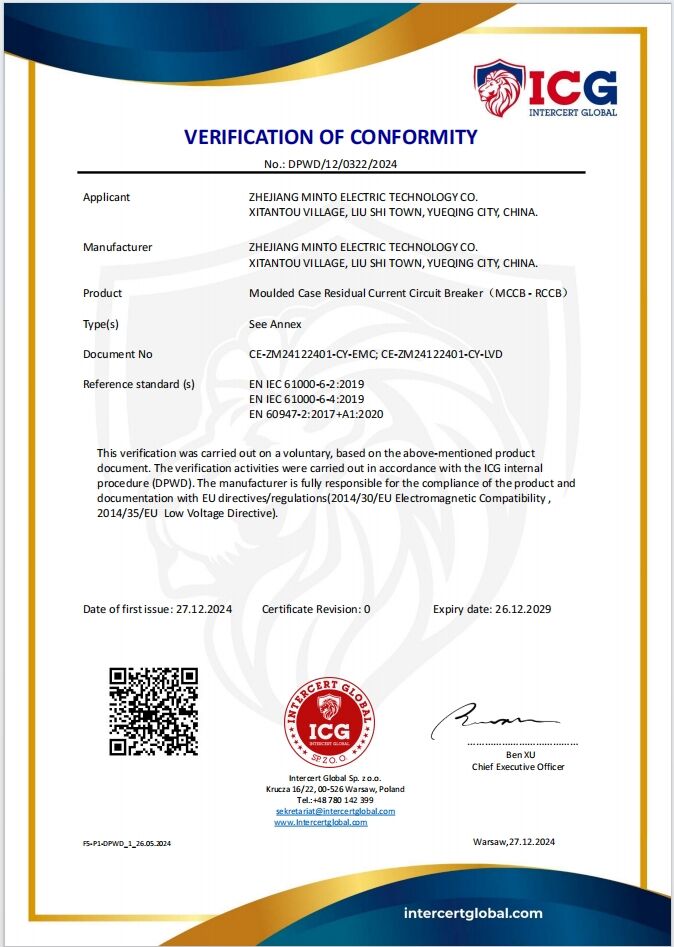

Сертификаттау: |

IOS CE ROHS |

Басып шығару коммерциялық шарттар

Азімдік тапсырыс саны: |

1 |

Баға: |

150$ |

Пакеттау мәліметтері: |

Аспан жұмыртқасымен пакеттеу |

Жеткізу уақыты: |

Он бес күн ішінде |

Төлем шарттары: |

алдын ала 100%, 70%/30%, 80%/20% |

Тамыр көбейтудің мүмкіндігі: |

Кез келген уақытта қолжетімді |

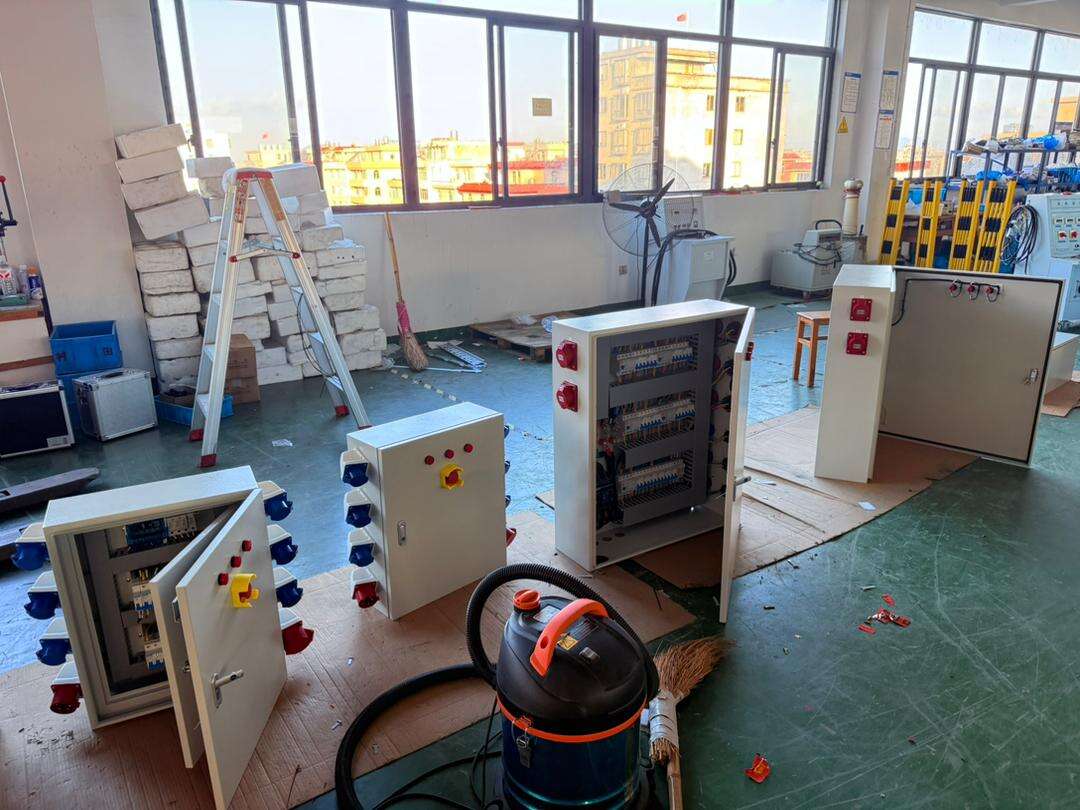

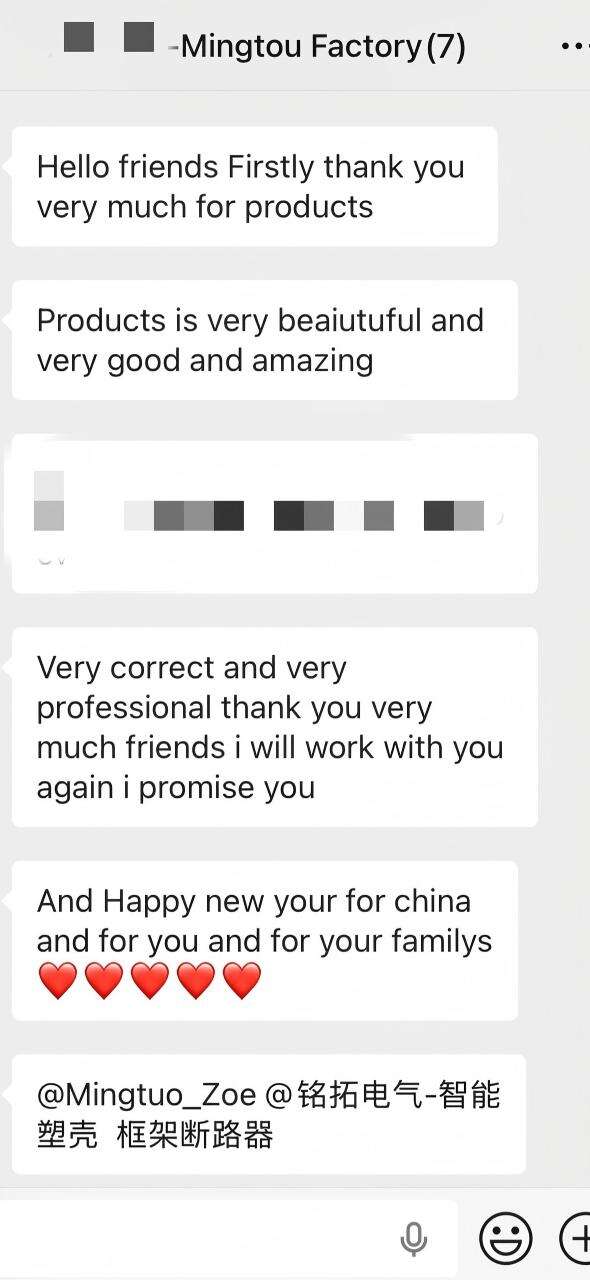

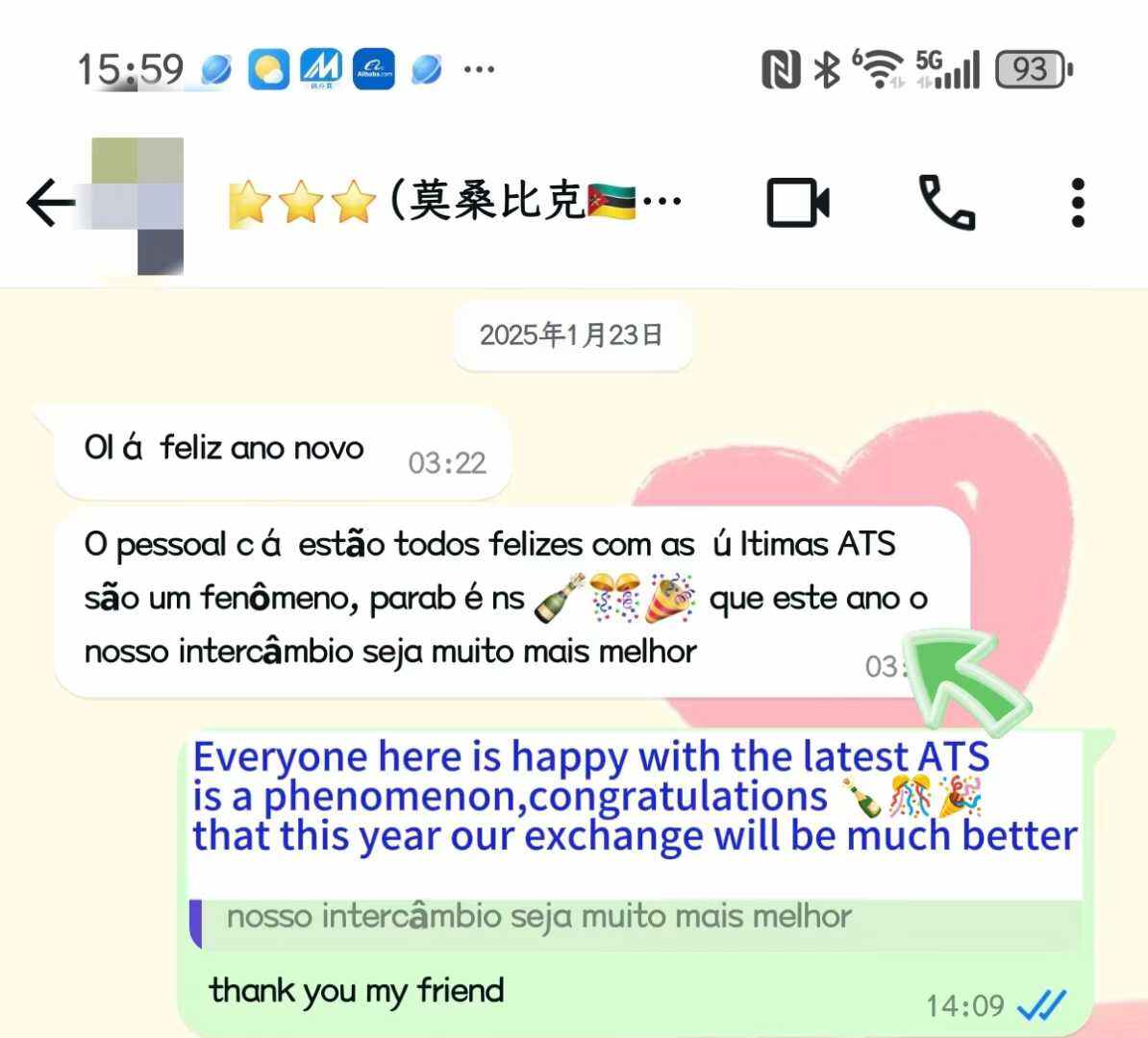

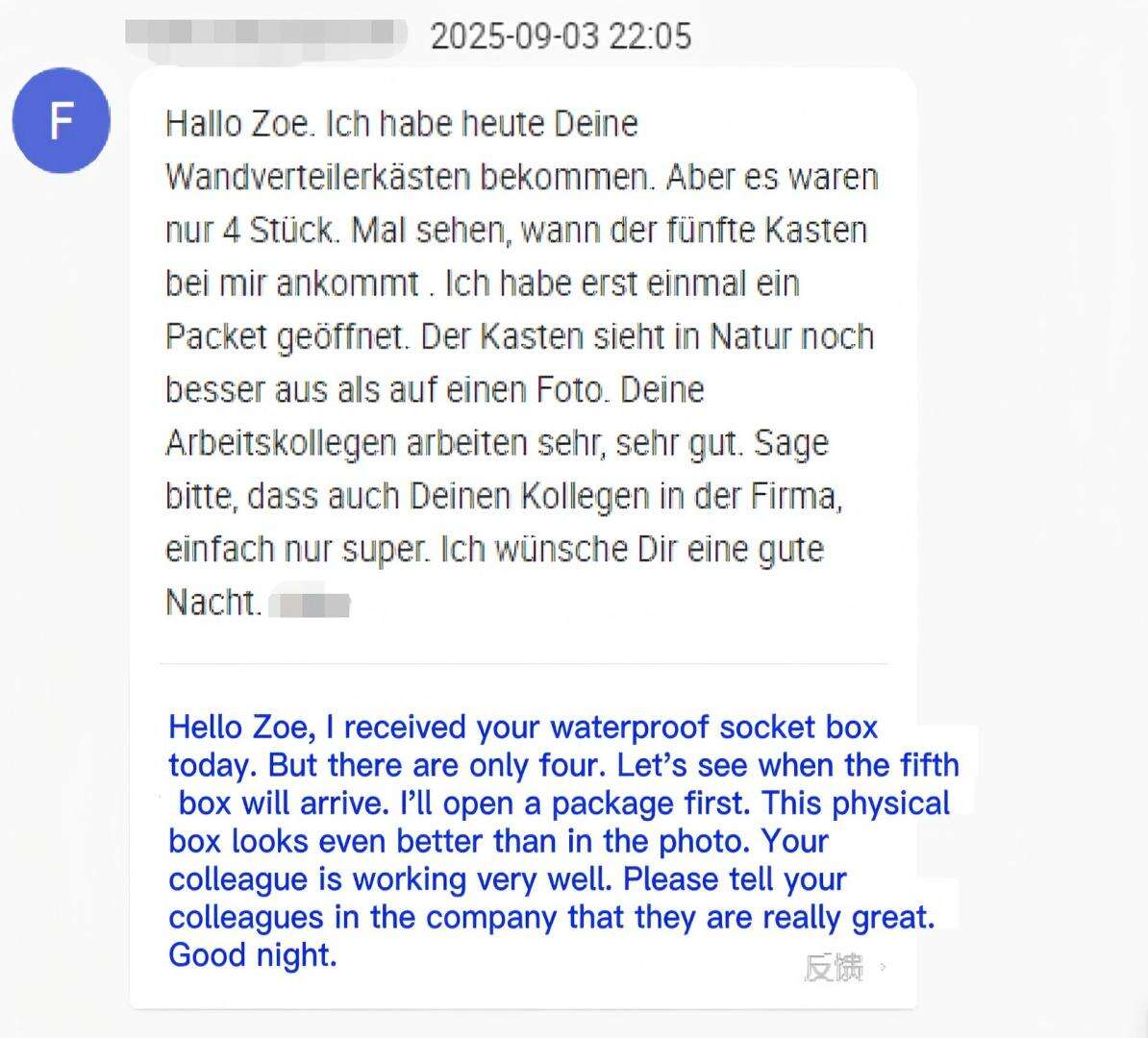

Біздің өндірістік деңгейдегі су өткізбейтін розеткалық қораптарымыз ылғалдық, шаң, діріл және механикалық соққылар әсер етуі мүмкін жағдайларда сенімді электрмен жабдықтау үшін идеалды шешім болып табылады. Әрбір құрылғының сыртқы қақпағы дәлме-дәл формалардан және күшейтілген герметикатция технологиясынан тұрады, бұл оның беріктігін ғана емес, сонымен қатар ең қатаң электр қауіпсіздік стандарттарын сақтауын қамтамасыз етеді. Бұл құрылғылар ішкі бөлшектерді қорғау жағынан үздік нәтиже көрсетеді және пайдаланушыларға қауіпсіз, тұрақты электр розеткасын ұсынады.

Розеткалардың басқа стилдері

| Германия стилі | Француз стилі | Универсал стиль | Оңтүстік Африка стилі | Ұлттық стилі | Бразильдық стилі |

|

|

|

|

|

|

|

|

|

|

|

|

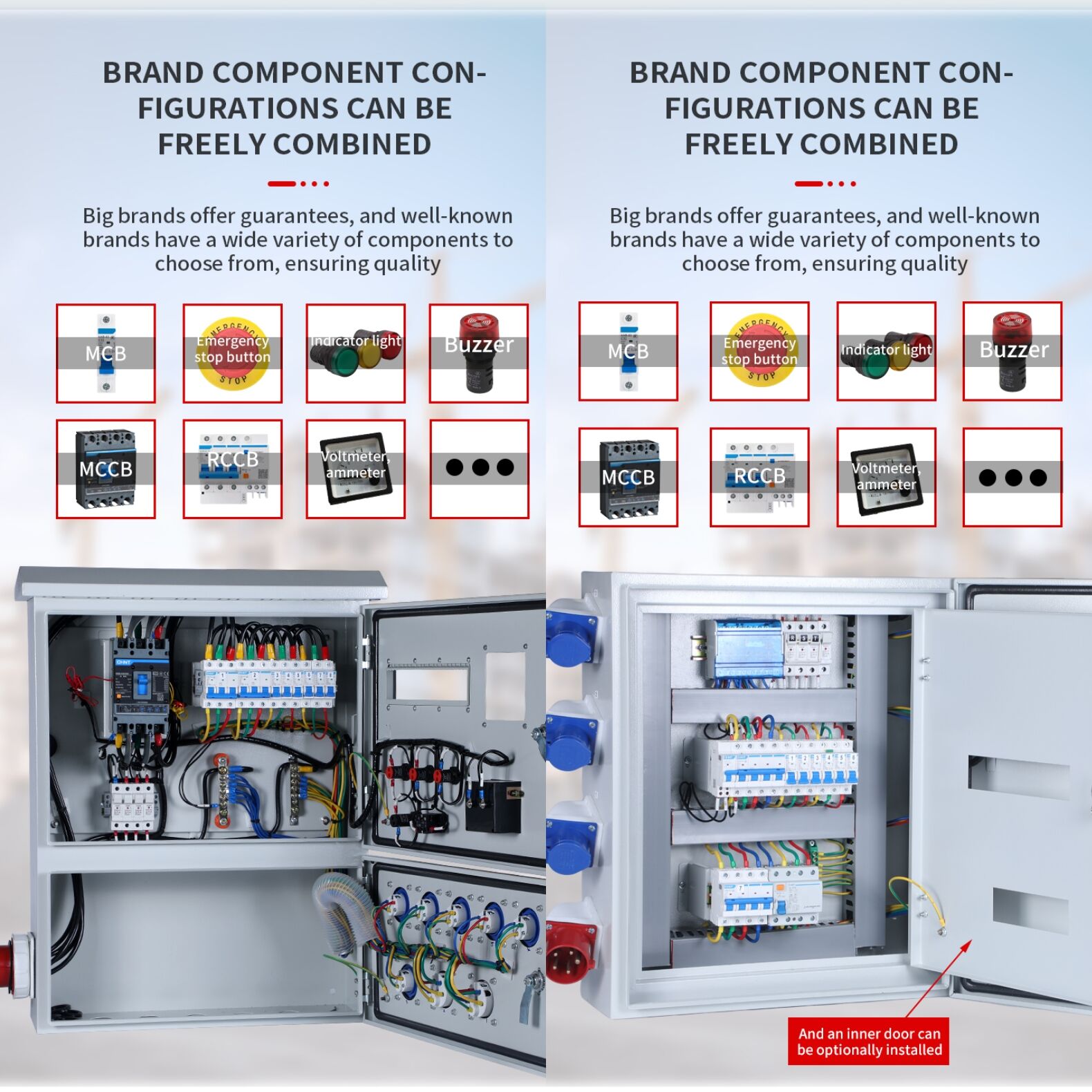

Жоғары деңгейдегі қорғау мен беріктікті негізге ала отырып, метал сувөткізбейтін розетка қорапшасы базалық тарату қорғау құрылғысынан электрлік компоненттердің бірнешеуін интеграциялау арқылы тарату, бақылау, басқару және қауіпсіздік туралы ескертулерді біріктіретін көпфункционалды интеллектуалды басқару терминалына дейін жетілдірілуі мүмкін. Негізгі кеңейту мүмкіндіктері мына төрт аспектіде көрініс табады:

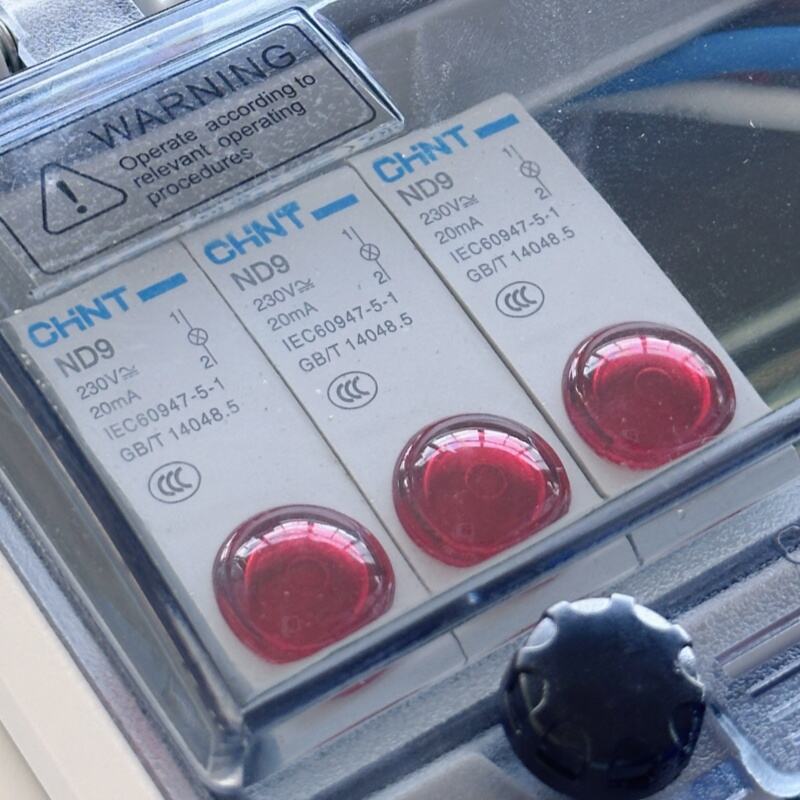

1. Күйді бақылау және көрсету

Ток/кернеу өлшеуіші немесе дисплейі интеграцияланған болып келеді, ол тізбектің электр параметрлерін нақты уақыт режимінде бақылайды, энергияны пайдалануды визуалдандырады және артық жүктемені болдырмауға, сондай-ақ ақауларды диагностикалауға мүмкіндік береді.

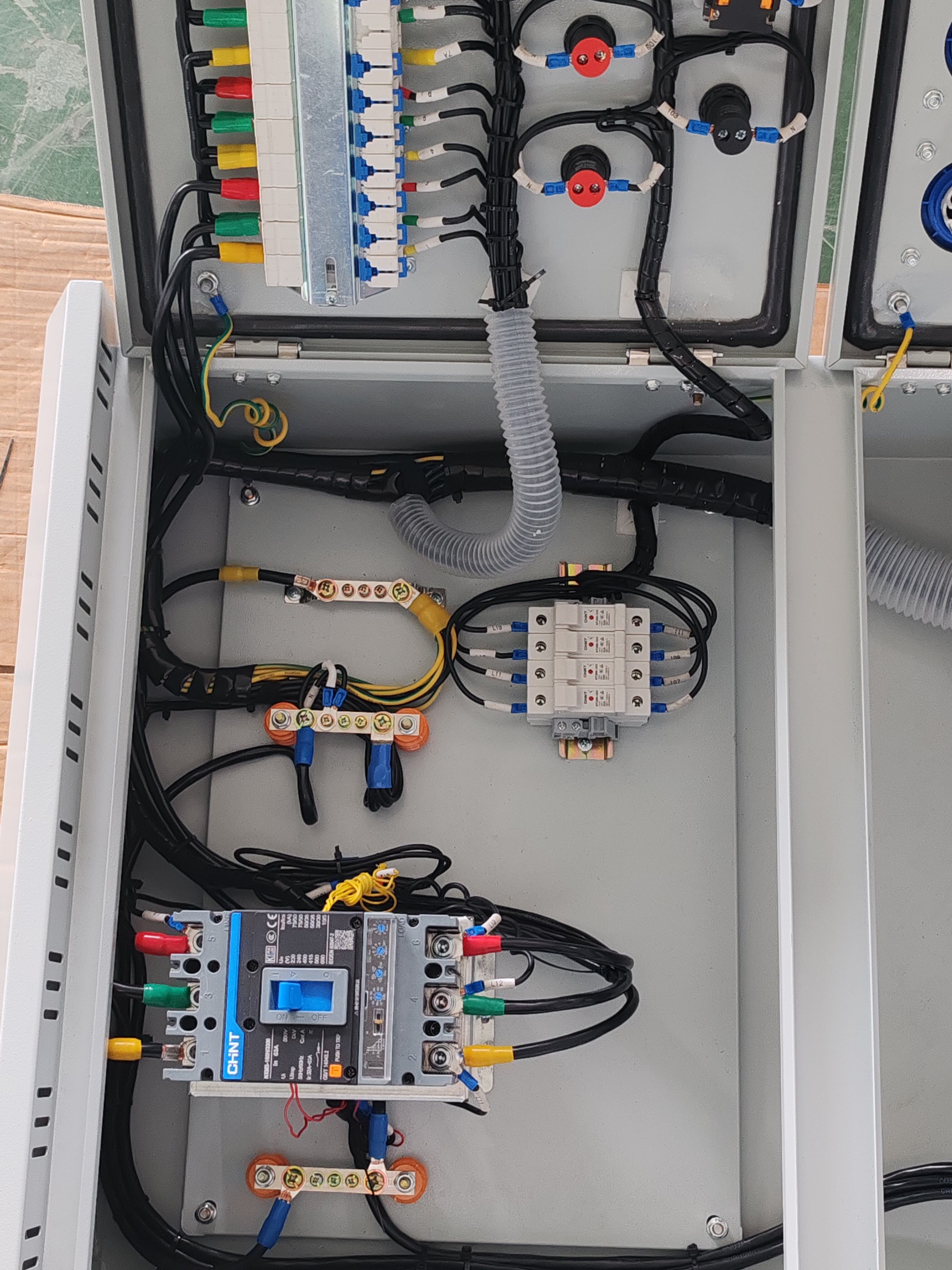

2. Негізгі басқару және қорғау

Контакторды қосу негізгі тізбектің алысқа жететін немесе автоматты ауыстыруын іске асырады; Сақтандырғыштар қысқа тұйықталу мен асырау жүктемеден сенімді қорғаныс ядроларын қамтамасыз етеді, бұл қораптың негізгі басқару және қорғаныс блогын құрайды.

3. Қауіпсіздік туралы ескерту және авариялық тоқтату

Фаза индикаторы қуат күйін көрнекі түрде көрсетеді; Дабыл хабарсіздік болған кезде дабыл шығарады; Авариялық тоқтату батырмасы авариялық жағдайда тез қуатты өшірудің әдісін ұсынады, осы үшеуінің бірігуі жұмыс істеу қауіпсіздігін және авариялық жағдайларға жауап беру мүмкіндігін әлдеқайда арттырады.

4. Модульді интегралды дизайн

Жоғарыда көрсетілген функционалды компоненттер стандартты қорапқа рейкалық орнату немесе қалдырылған интерфейстер арқылы икемді және тығыз интеграциялануы мүмкін, функцияларды тапсырыс бойынша комбинациялауға жеткізіп, жалпы IP қорғаныс деңгейін сақтайды.

|

|

|

|

|

|

|

|

|

Орталықтандырылған орналасу:

Көп розеткалы қолдау:

|

|

|

|

|

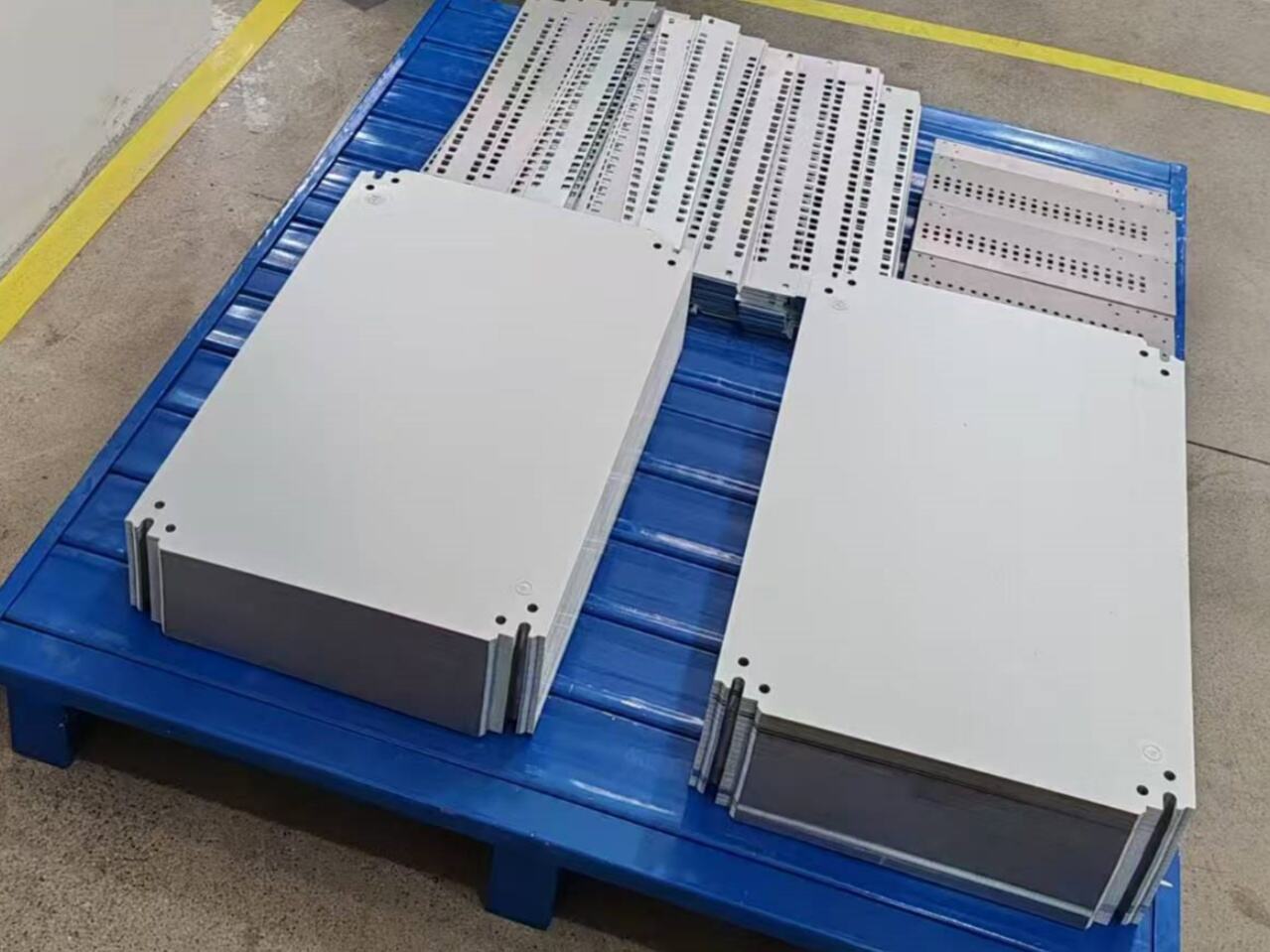

Жоғары сапалы материалдар: Жоғары беріктікке ие, коррозияға төзімді суық тартылған болат пластиналардан, нержавейкалық болаттан (мысалы, 304/316, коррозия әсері жоғары орындарда қолданылады) немесе алюминий құймалардан жасалады.

Беттік өңдеу: Майсыздандыру, фосфаттау және электростатикалық бояу сияқты процестер арқылы мықты және жабысымды антикоррозиялық қабат түзіледі. Сыртқы орындарға арналған үлгілерде ультракүлгін сәулелерге төзімді бояу болуы тиіс.

Қорап қақпағының тығыздығы: Қорап қақпағы мен қорап денесінің қосылатын жерінде жоғары сапалы силиконды тығыздағыш орнатылған, бұл қақпақтың тығыз басылуын және көп жылдар бойы пайдалану кезінде старение немесе трещин пайда болмайтынын қамтамасыз етеді.

Кіріс пен шығыстың тығыздығы: су өткізбейтін кабельдық гильза (резьбалы сақина) немесе сындырылатын тесік + тығыздағыш сақинамен жабдықталған, кабель енгізілгеннен кейін де тығыздық сақталады

Пластина қалыңдығы: Сыртқы қорап болаты жеткілікті қалыңдықта (мысалы, ≥ 1,2 мм) болуы керек, бұл қораптың беріктігін, соққыға төзімділігін және деформацияланбауын қамтамасыз етеді.

Есік құлыбының құрылымы: Құлып су жинақталуға қарсы жобаланған және құлып тесігіне су түсіп кетуді болдырмау үшін жергілікті герметизацияланған.

Жерге қосудың үздіксіздігі: Қорапта арнайы жерге қосу терминалы бар және қорап металдық бөлігімен сенімді байланысып, электр қауіпсіздігі қамтамасыз етіледі.

|

|

|

1. Бөлу және функционалдық тестілеу

Сатылап ток беру: Алдымен негізгі ажыратқышты қосыңыз, одан кейін салалық ажыратқыштарды біртіндеп қосыңыз (мысалы, ағып кету қорғау құрылғылары мен автоматты ажыратқыштар), ешқандай аномалиялар бар-жоғын бақылаңыз (мысалы, айқайлар немесе өшіп қалу).

Кернеуді тексеру : Кернеуін әрбір розетканың кернеуін өлшеу үшін мультиметрді пайдаланыңыз, фазалық кернеудің (мысалы, 220 В ± 10%), фазалардың ретінің (егер үш фазалы розеткалар болса) қалыпты екендігін және нөлдік жерге түсетін кернеудің 0 В-қа жақын екендігін растаңыз.

Полярлықтық тесті: Полюстіктің "сол жақта нөл, оң жақта фаза және жерге қосу" дұрыс екенін растау үшін фаза детекторын (кернеу тестерін) әрбір розеткаға енгізіңіз.

2. Қорғаныс функциясының тексерілуі

Қорғаныс функциясын тексеру: Әрбір ақаулық қорғаныс құрылғысындағы "ТЕСТ" түймесін басу кезінде ол дереу жұмыс істеуі керек, бұл токтың қашып кетуін қорғау функциясының тиімділігін көрсетеді.

Қосу/Өшіру тексерілуі: Әрбір тумблерді басып, оның сәйкес розетканың қосылуын/өшірілуін қалыпты түрде басқара алатынын растаңыз.

3. Жүктеме Тестілеу және Соңғы Тексеру

Жүктеме жұмысы: Нақты жүктемелерді (мысалы, бұрғылар, шамдар) немесе жасанды жүктемелерді қосып, қысқа уақытқа жұмыс істетіңіз және розеткалардың, тумблерлердің және сымдардың қызып кетуі, дыбыс шығаруы немесе кернеудің төмендеуі сияқты аномалиялары бар-жоғын бақылаңыз.

|

|

Біз сызбалардан бастап дайын өнімге дейін толық шешім ұсынамыз, негізгі артықшылығымыз:

Бақыланатын үдеріс: Құрамын және тесіктерді дәл схемалық сызба бойынша таңдауға қатаң сәйкестендіріңіз, дәлдікті және дұрыстықты қамтамасыз етіңіз.

Толық қызмет көрсету: жинақтау, қателерді жою және тапсырыс бойынша стикерлерді желімдеу (мөлшерден тыс су өткізбейтін PVC материалды опция ретінде) және басқа да біркелкі қызметтер кіреді.

Тұрақты жеткізіп беру: Металл модельдерінің айлық өндіріс қуаты 300 дананы құрайды, жеткізу тиімділігі мен масштабтық талаптарға кепілдік береді.

|

|

|

|

|

|

|

|

-Ішкі жәшіктеу

Соққыға төзімді материал

Материал: тозаң, көбік пленка т.б.

Орналастыру: Қорғау құрылғысының айналасына, жоғарғы және төменгі жағына біркелкі орналастырыңыз

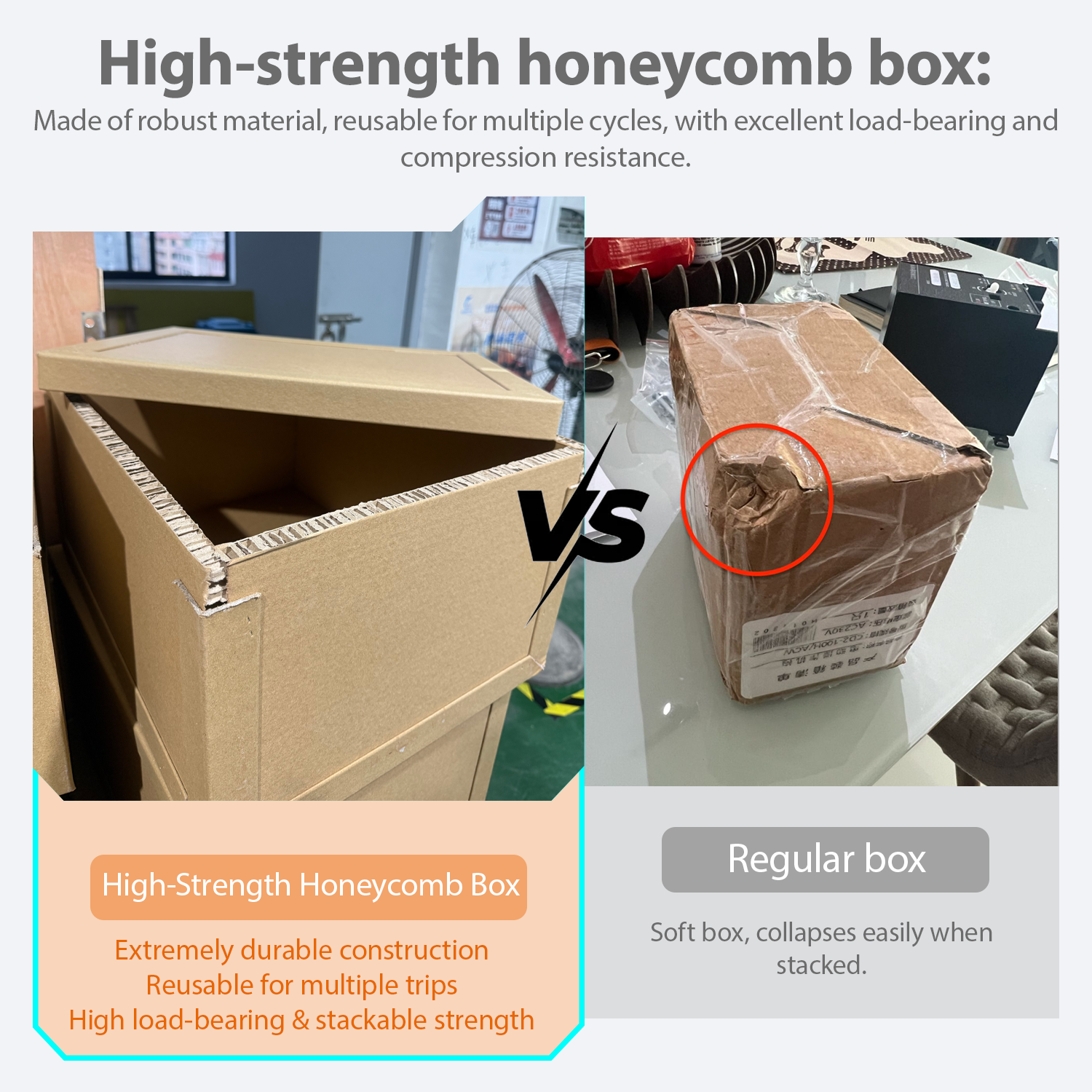

-Сыртқы жәшіктеу

Картондік тобезек

Материалы: Биік беріктікті қабыршақты картондік куту

Коробка қапталу

Әдісі: Мен бағалау арқылы лента немесе бау

Талап: Қорап тресінің пайда болуын болдырмау үшін қораптың сынуы

Идентификациялау және таңбалау

Мазмұны: Өнімнің моделі, саны, салмағы, шығарған компания, тасымалдау белгісі (мысалы, сынғыш, жоғарыға қарай, ылғалдылыққа қарсы және т.б.)

Орналасуы: картон қораптың сырт жағына бәрін айқын көрінетіндей етіп басып шығару керек.

Құрылымдық беріктік

Ұяшықтық құрылымдық дизайн қысымды тиімді таратуға мүмкіндік береді, жоғары сығылуға төзімділігі бар, көп жүкті көтеруге қабілетті және оңай деформацияланбайды.

Қораптың жиегі жалпы тұрақтылықты арттыру үшін күшейтілген, сондықтан оны қабаттап орналастыруға және тасымалдауға қолайлы.

Материалдық ұзақ уақыт қолдану

Жоғары беріктікті толқынды қағаз, пластик немесе кешенді материалдар жиі қолданылады; олар жеңіл салмақты және тозуға төзімді.

Суға және ылғалға төзімді өңдеу (мысалы, бояу немесе пленкамен жабу), әртүрлі орталарға сәйкес келеді.

Буфердеу қабілеті

Ұяшықтық негіз қабаты жақсы соққыға төзімділік қасиетін қамтамасыз етеді және ішіндегі заттарды соқтығысу кезіндегі зақымдан қорғайды.

Тесік диаметрі мен қалыңдығы қажеттілікке қарай таңдалуы мүмкін, қорғаныс пен көлемнің пайдаланылуы арасында тепе-теңдік орнатылады.

|

|

|

Үй ішілік көліктік

Қытайдың көрсетілген жүк тасымалдаушысы бар болса, өнімдерді көрсетілген орынға арқылы тасымалдаймыз жол Транспорті немесе үй ішілік экспресс өндіріс аяқталғаннан кейін жеткізу

Бейнеулы қозғалыс

Тауарлардың саны аз және уақыт шектеулі болғанда, шетелге көрсетілген орынға жеткізу керек болса тасымалдау үшін үш ірі халықаралық экспресс жеткізу компаниялары таңдалады DHL, FEDEX, UPS

Теңіз көлігі/әуе көлігі

Егерістің мөлшері көп болғанда және уақыт қатал емес болса, біз теңіз арқылы тасымалдауды таңдаймыз. Біз тиісті жүк көтеру компаниясын таңдаймыз, олар товарды алу үшін автокөліктерді жіберіп, оны келісімге сәйкес портқа жеткізеді қоймалау . Содан кейін товар соңғы шетел портына теңіз арқылы жеткізіледі де, тауарды алу үшін клиенттің өзі құжаттармен келуі қажет жүк құжаты .

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Өнеркәсіптік суға төзімді розетка қорабы қатаң түрде әсер ететін орта жағдайында сенімді электрмен жабдықтау жүйесі, жабдықтардың бір-біріне қосылу блогы және тізбекті қорғау құрылғысы ретінде жұмыс істейді. Құрылғының негізгі мақсаты тұрақты электрмен жабдықтау көзі болып табылады және сонымен қатар пайдаланушылар мен жабдықтарды ортаның қауіпті әсерлерінен қорғау.

IEC 60529 және IEC 60309 бойынша жасалған, әрбір құрылғы мынадай сынақтан өткізіледі:

Қораптарымыздың герметизациялық өнімділігі — ең жоғары сапалы еуропалық герметизация технологиясы мен күшейтілген корпус конструкциясының арқасында, тіпті ең қиын жағдайларда да ұзақ қызмет ету мен тұрақты суға қарсы қасиеті қамтамасыз етіледі.

Суға төзімді розетка қораптарымыз жабық технологияны жапондық сапалы шебердің неміс дәлдігімен үйлестіреді, сондықтан олар жалпы нарықтағы өнімдерге қарағанда 40% ұзақ жұмыс істейді және герметиктік өнімділігі 50% жоғары, сонымен қатар техникалық қызмет көрсету құны 60% дейін төмендейді.