5th Floor, No. 3, Jinghong West Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province +86-13057710980 +86-18334450116 [email protected]

CONTACTOR

|

|

AC contactor is an electrical control device widely used in automation control systems for remote connection and disconnection of AC power circuits. It mainly consists of an electromagnetic system, a contact system, an arc extinguishing device, and auxiliary components.

When the electromagnetic system is powered on, the generated magnetic field will attract the contacts to close, thereby connecting the circuit;

When the power is cut off, the magnetic field disappears, and the contacts separate by spring force or other mechanical devices, disconnecting the circuit.

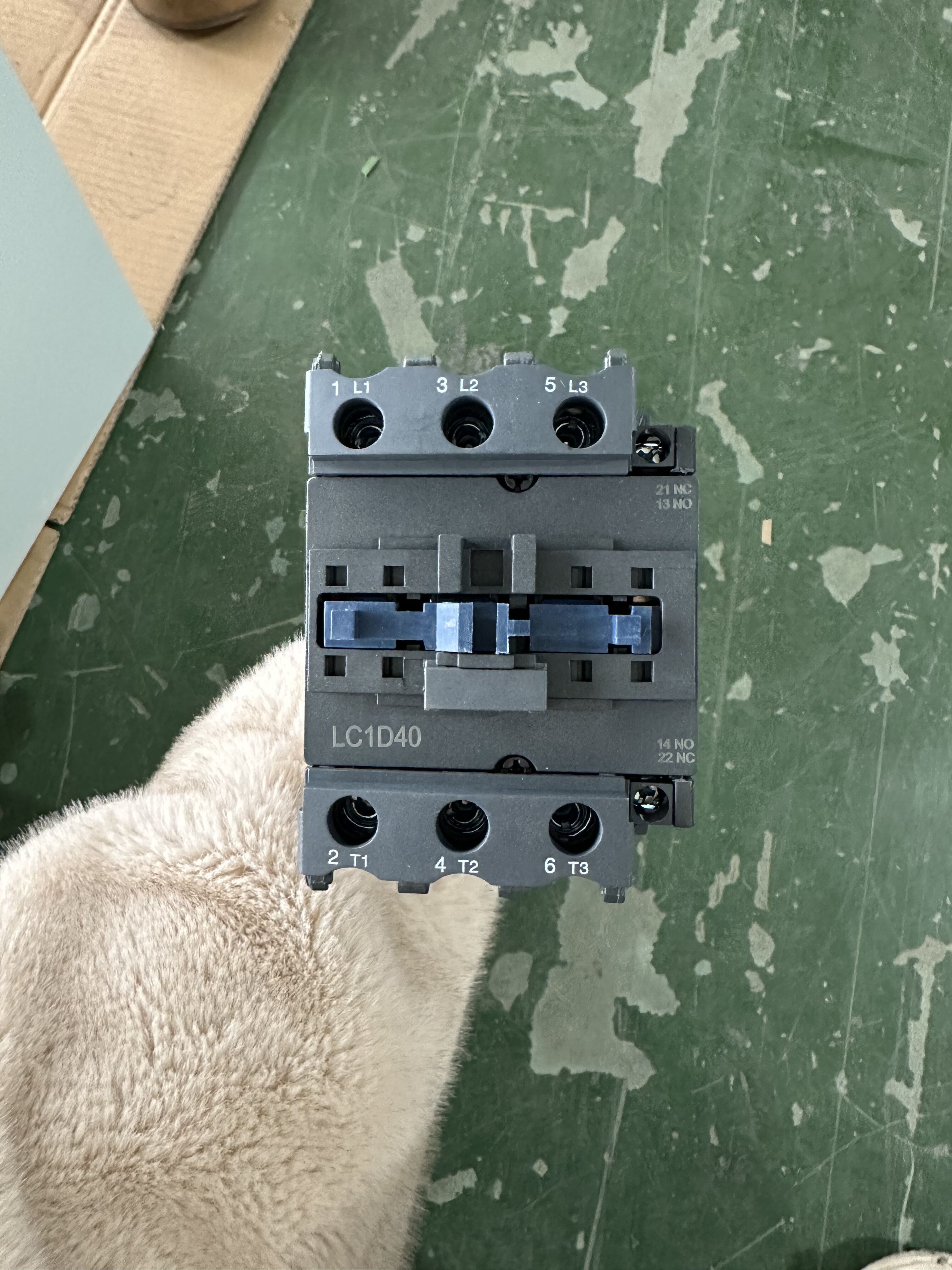

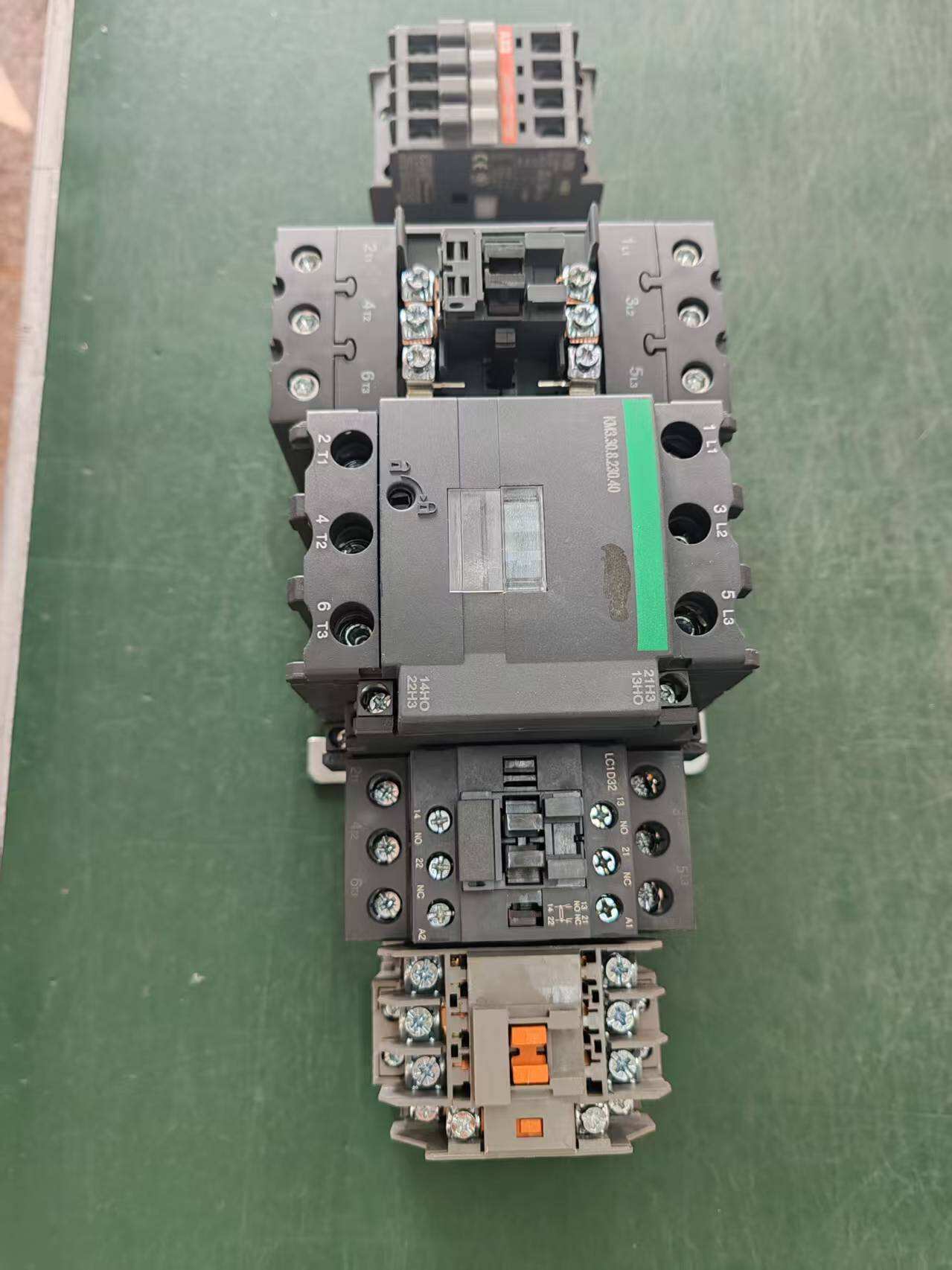

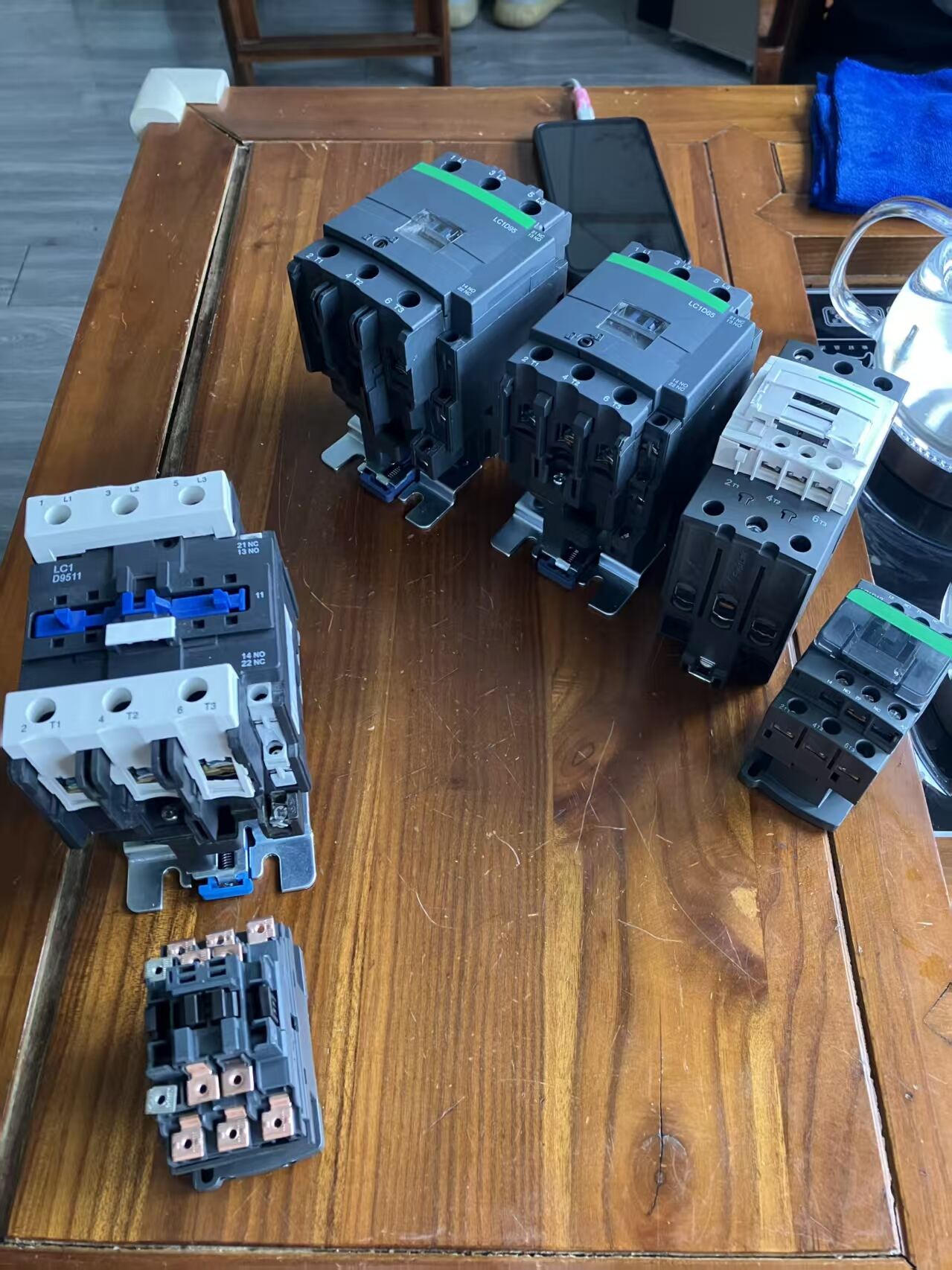

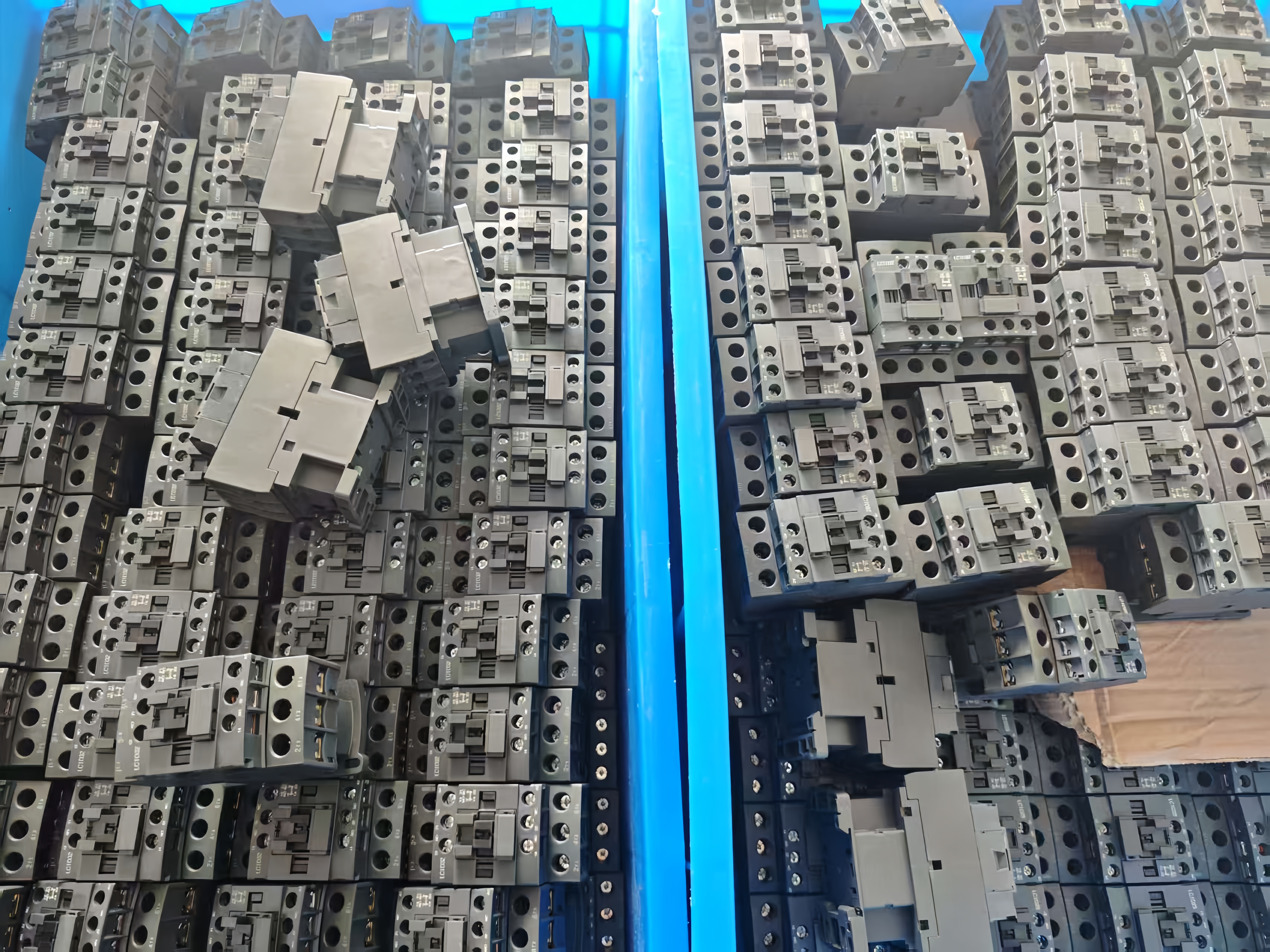

The MINGTUO LC1D AC Contactor Series provides switching that is reliable and efficient for various control and protection applications of AC. Using high-quality components of an electromagnet and contacts that are wear-resistant, the contactors keep very good electrical performance even after a long service life. Their small design and modular accessory layout allow them to be the perfect solution for integration into industrial machines, control cabinets, and automated systems.

|

Working principle: The working principle of an AC contactor is based on electromagnetic effects, and its core function is to control the power on and off of the electromagnetic coil to achieve the closure and disconnection of the main contact, thereby controlling the connection and disconnection of the load circuit.

AC contactors are usually equipped with auxiliary contacts for control or signal transmission. Auxiliary contacts can be of the normally open (NO) or normally closed (NC) type, which change state with the action of the main contact and are used to achieve interlocking, signal indication, or other control functions. |

|

Specification Details:

Minimum Order: Quantity 1

Price:USD 3-9

Packaging:Carton

Delivery Time:Within 15 days

Payment Terms:100% Prepaid / 70%-30% / 80%-20%

Supply Ability:Ready to ship

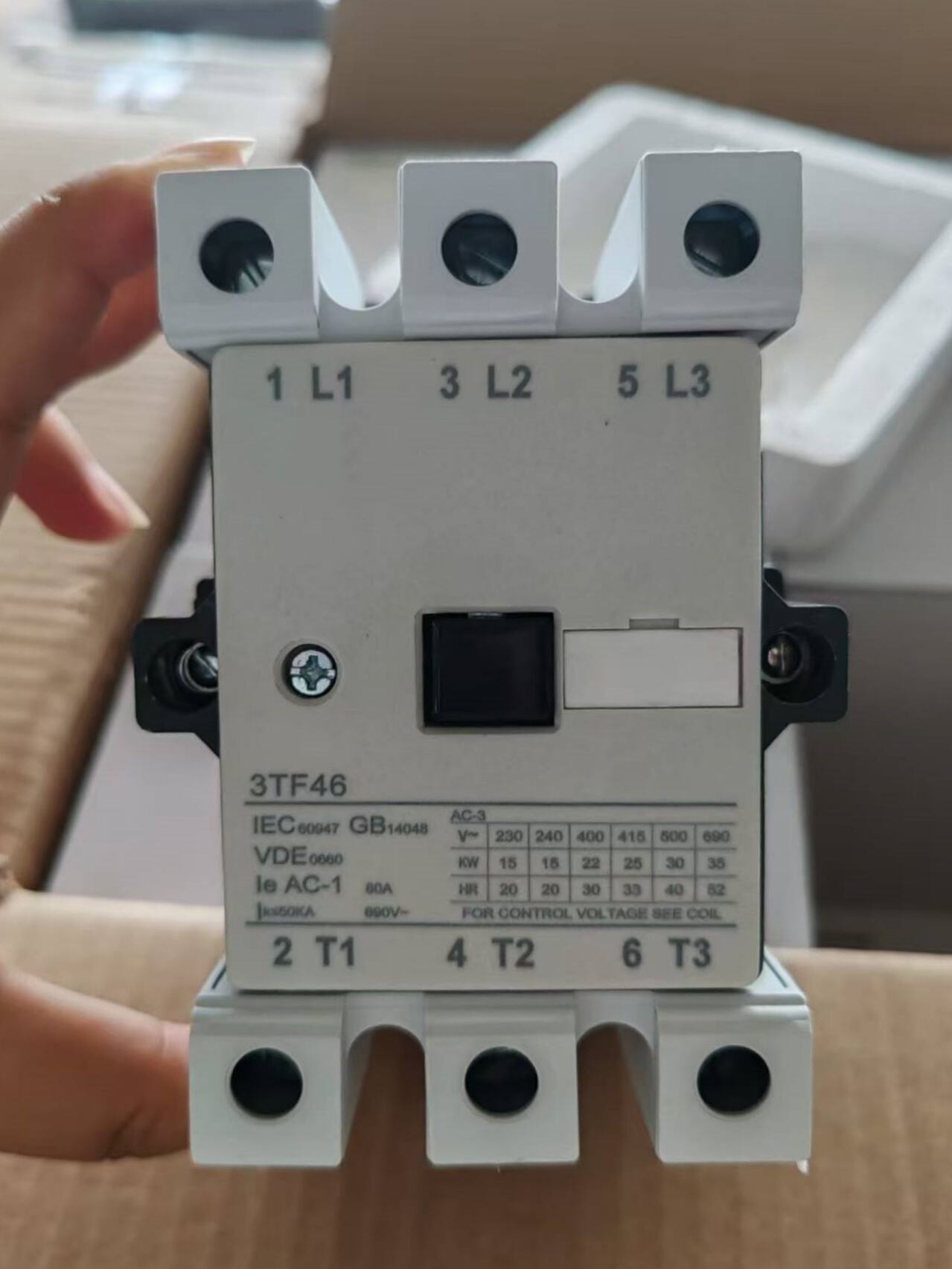

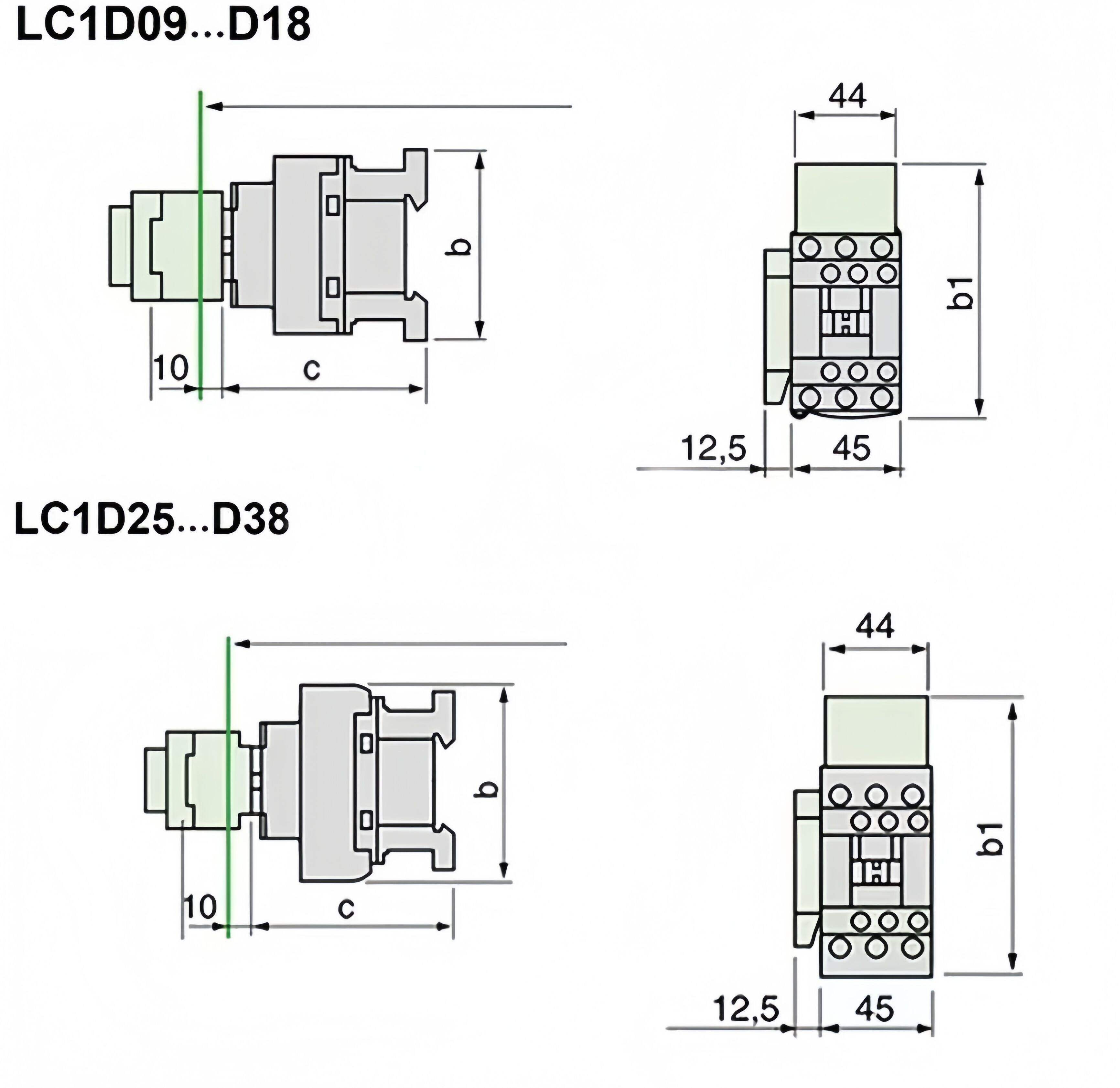

| Rated Current | 9A–95A | Control Voltage | AC/DC 24V–500V |

| Rated Operating Voltage | AC 220V / 380V / 660V | Mechanical Life | 10–30 million cycles |

| Pole Options | 3-Pole / 4-Pole | Electrical Life | 1–3 million cycles |

|

|

|

|

|

|

AC contactors are the key elements in power control systems that enable remote and automated switching of high-power loads by low-power control circuits. Due to their quick reaction, long service life, and safe separation capability, they are the perfect choice for those applications which require frequent switching and reliable protection.

|

PRODUCT MODEL |

WORKING CURRENT |

RATED POWER | CONVENTIONAL THERMAL CURRENT | |

| 220/240V | 380/400V | |||

| LC1D09 | 9A | 2.2KW | 4KW | 25A |

| LC1D12 | 12A | 3KW | 5.5KW | 25A |

| LC1D18 | 18A | 4KW | 7.5KW | 32A |

| LC1D25 | 25A | 5.5KW | 11KW | 40A |

| LC1D32 | 32A | 7.5KW | 15KW | 50A |

| LC1D38 | 38A | 9KW | 18.5KW | 50A |

| LC1D40 | 40A | 11KW | 18.5KW | 60A |

| LC1D50 | 50A | 15KW | 22KW | 80A |

| LC1D65 | 65A | 18.5KW | 30KW | 80A |

| LC1D85 | 85A | 22KW | 37KW | 125A |

| LC1D95 | 95A | 25KW | 45KW | 125A |

|

|

|

|

|

|

|

|

|

|

|

|

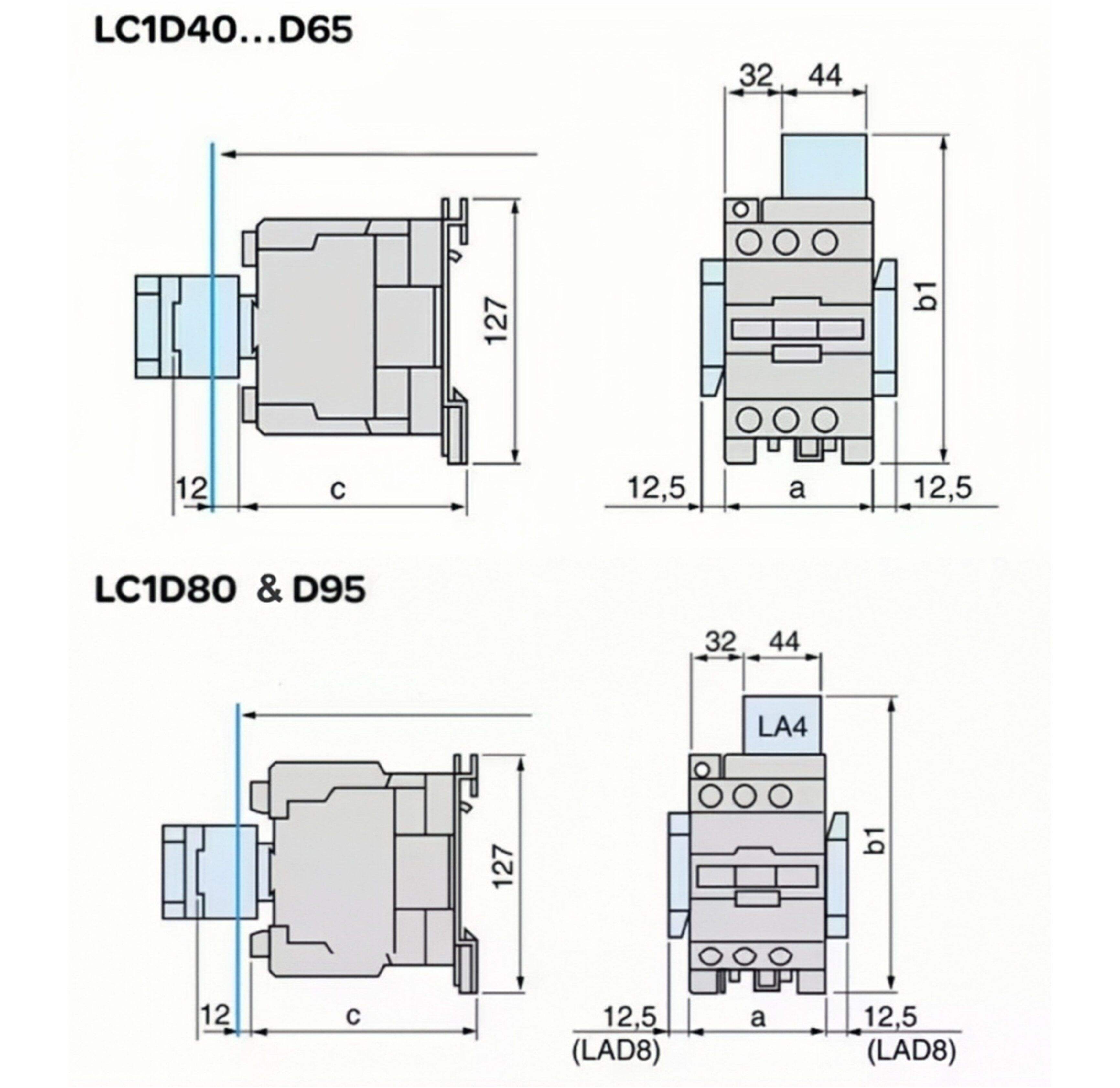

| Aluminum coil | Copper coil |

|

|

Our product uses copper coils, and we do not recommend choosing products with aluminum coils

1. Conductivity and efficiency

Copper coil: low resistivity, better conductivity

Aluminum coil: high resistivity

2. Mechanical strength and durability

Copper coil: high mechanical strength, wear resistance, fatigue resistance

Aluminum coil: The material is relatively soft and prone to deformation

3. Corrosion resistance and stability

Copper coil: Strong resistance to oxidation and corrosion

Aluminum coil: prone to oxidation

|

|

|

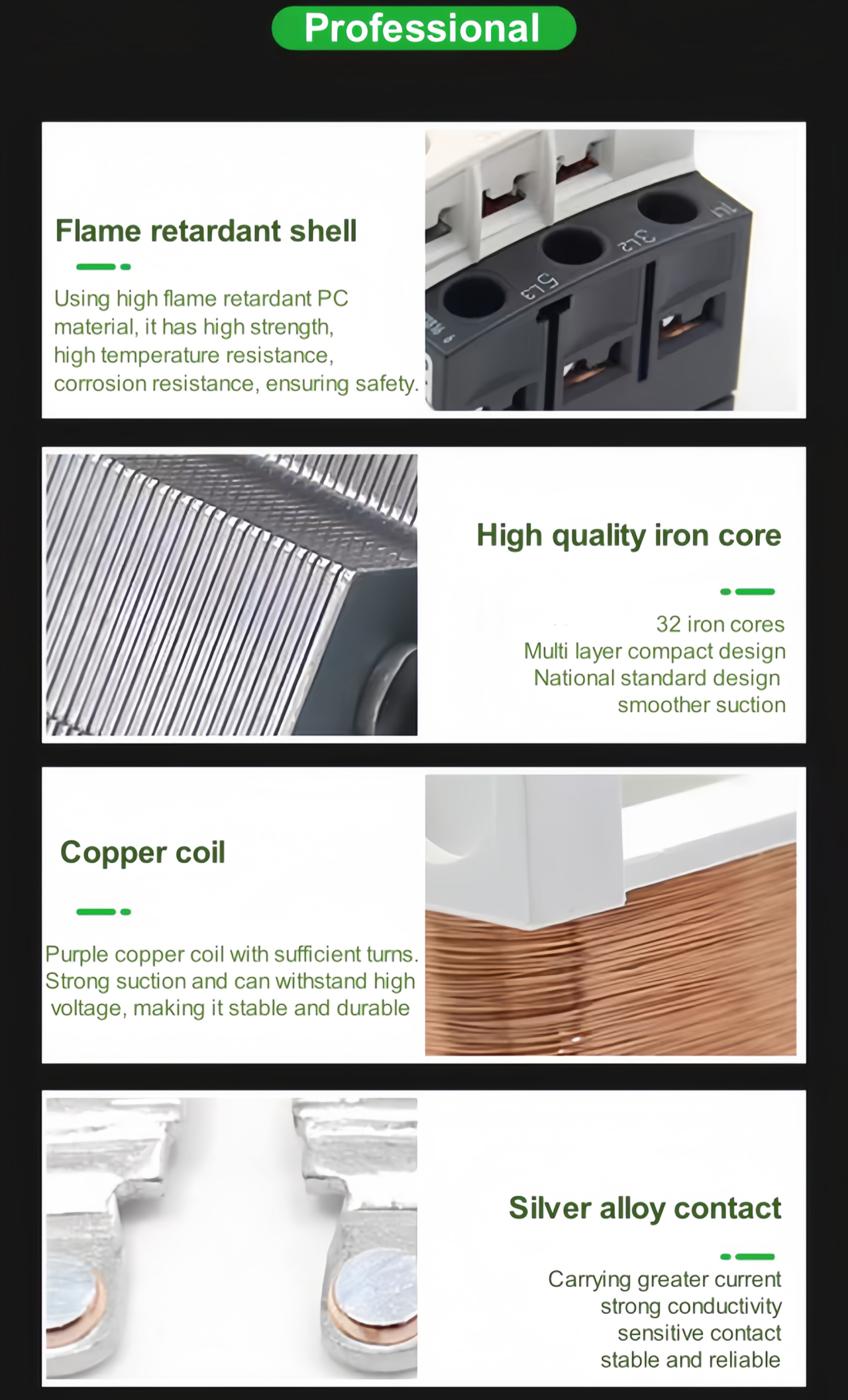

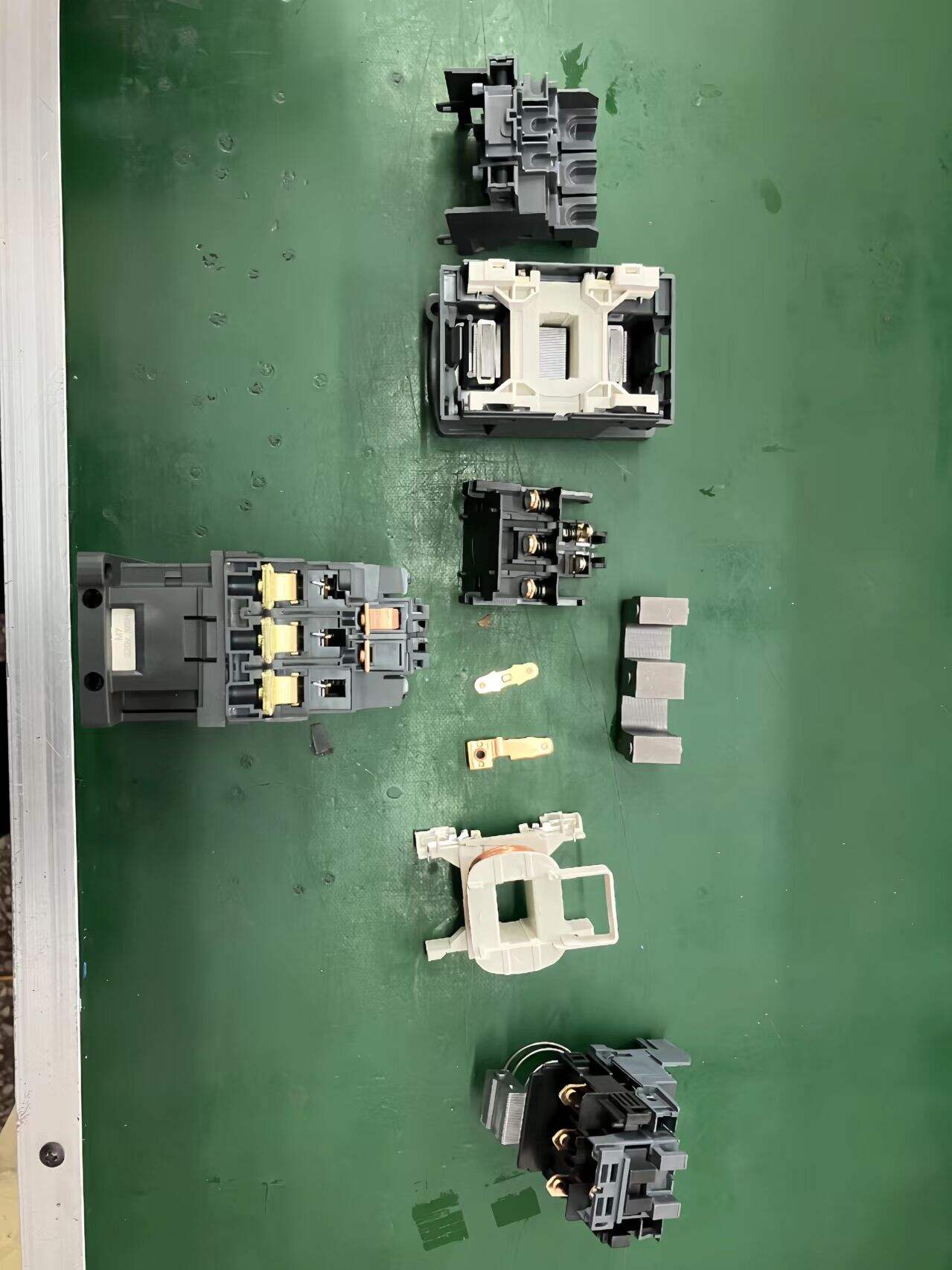

Process 1: Preparation and Inspection of Components

Workers manually sort all components such as iron cores, coils, contacts, springs, plastic shells, etc., and conduct visual inspections.

Process 2: Assemble the core components

Iron core assembly: Manually install E-type silicon steel sheets and short-circuit rings, and may use simple fixtures to ensure alignment.

Coil installation: Insert the wound coil into the iron core.

Contact system assembly: Manually install the moving and stationary contacts onto the contact support and wiring terminals, which may require manual riveting.

Process 3: Final Assembly

Workers manually assemble various parts such as the action mechanism, electromagnetic system, contact system, and arc extinguishing cover onto the plastic shell or base plate. Tools such as screwdrivers and pneumatic screwdrivers are required to tighten the screws.

Process 4: Manual testing

Mechanical characteristic test: Workers manually press the contactor to check whether the action is flexible and stuck.

Simple electrical test: Use temporary wiring, connect low voltage electricity, listen for the sound of suction/release, and use a multimeter to check the continuity of the contacts.

Process 5: Cleaning, Labeling, and Packaging

Manually clean the appearance, paste model labels and certification labels, and finally manually pack the boxes.

|

|

|

|

Inner packaging

Shockproof material

Material: foam, bubble film, etc

Placement: Place evenly around the circuit breaker, at the top and bottom

External packaging

Carton

Material: High strength corrugated cardboard box

Carton sealing

Method: Seal with tape or strapping

Requirement: Ensure a secure seal to prevent cracking of the box

Identification and labeling

Content:Product model, quantity, weight, manufacturer, transportation label (such as fragile, upward, moisture-proof, etc.)

Location: Clearly printed on the outside of the cardboard box.

Featuring precisely engineered high-precision components and sophisticated electromagnetic design, our AC contactors along with the 3-Pole Electrical Power Relay series are the perfect solution for your power switching needs. They boast a long service life, excellent electrical durability, and stable operation even when subjected to harsh industrial environments. These are the key features which give our products an edge over the rest of the world.

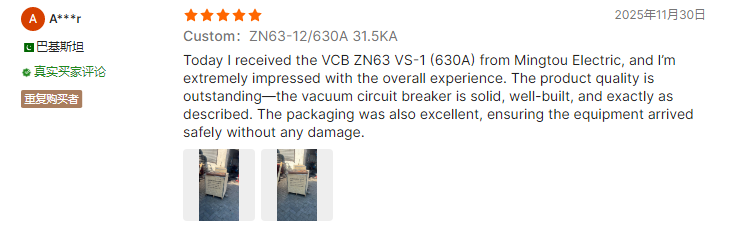

Inspection is done at the factory and up to the very last unit, the checks include:

Customer feedback

|

|

|

|

|

|

|

|

|

|

|

|

Certificate

|

|

|